Introduction: The UK’s Push for Stronger Foundations

In the United Kingdom, infrastructure development is rapidly evolving. From offshore wind farms in the North Sea to urban bridges and tunnels across England, contractors require reliable equipment that combines efficiency, safety, and sustainability.

This is where BRUCE Hydraulic Pile Hammers stand out as the trusted choice for deep foundation works.

👉 Learn more about BRUCE Hydraulic Pile Hammer Features

Why the UK Prefers Hydraulic Pile Hammers

According to the Institution of Civil Engineers (ICE, 2023), hydraulic systems are now the preferred piling solution in the UK because they:

-

· Deliver quieter operation, crucial in noise-regulated cities like London and Manchester

· Offer adjustable impact control for mixed soils in England and Scotland

· Perform reliably in offshore renewable projects, especially wind farms

Unlike diesel hammers, hydraulic technology ensures compliance with UK environmental standards while maximizing driving power.

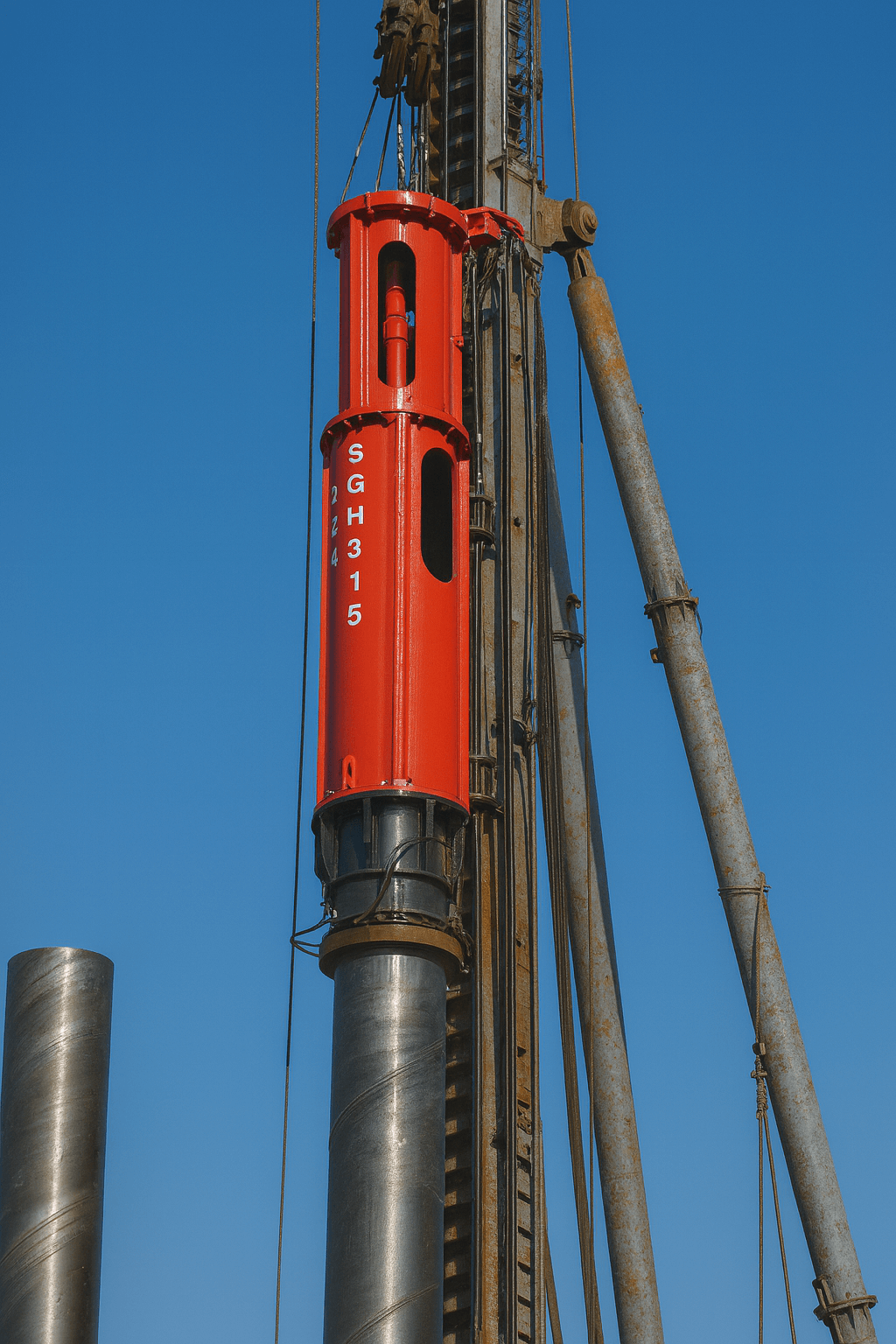

BRUCE – A Leading Hydraulic Pile Hammer Supplier in the UK

With over 25 years of expertise, BRUCE Piling Equipment has become a leading supplier of hydraulic pile hammers trusted by UK contractors.

Its product range includes:

· High-capacity Hydraulic Impact Hammers for deep foundations

· Hydraulic Vibro Hammers for efficient pile driving and extraction

· Customizable Power Packs and control systems

📌 Explore our Hydraulic Pile Hammer Specifications

Technical Advantages for UK Construction

BRUCE Hydraulic Pile Hammers are designed with:

· Precision Control – adjustable blow energy for clay, chalk, or marine soils

· Noise-Reduction Housings – essential for projects near residential areas

· Remote Monitoring Systems – allowing safe operation in confined sites

· Durability – ISO-certified materials built for long-term use

These features make them ideal for UK’s offshore energy sector, bridge foundations, and large-scale urban infrastructure.

Case Study: Offshore Wind Energy in England

In a 2024 UK Offshore Energy Report, hydraulic hammers reduced pile installation times by 27% compared to diesel hammers.

BRUCE models were noted for their high stroke precision and noise-suppression housings, which allowed projects in the North Sea to meet strict environmental regulations.

👉 Read more: Vibratory Hammer Pile Driving Insights

Benefits for UK Contractors

· Faster project delivery – shortened piling cycles

· Compliance with UK noise and emission standards

· Cost efficiency – less downtime and maintenance

· Flexibility – suitable for urban, marine, and infrastructure works

📌 Discover more at our Hydraulic Pile Hammer Glossary Resource

Frequently Asked Questions

Q1. Can BRUCE Hydraulic Pile Hammers be used in UK offshore projects?

Yes, they are already in use for wind farm foundations in England and Scotland, with proven environmental compliance.

Q2. How do they perform in UK London urban areas?

Their low-noise housings and precision stroke control make them perfect for London, Manchester, and Birmingham infrastructure projects.

Q3. What piles can they drive?

Steel casings, concrete piles, sheet piles, H-beams, and marine caissons.

Conclusion: Building the UK’s Future with BRUCE

The demand for efficient and sustainable piling equipment in the United Kingdom London continues to rise.

With ISO-certified technology, proven offshore performance, and urban adaptability, BRUCE Hydraulic Pile Hammers are positioned as the go-to solution for UK contractors.

👉 Visit Powerquip Official Website

👉Contact BRUCE Piling Equipment for tailored UK project solutions

👉 Connect with us on LinkedIn

👉 Explore visuals on Pinterest