U.S. Foundation Engineering on the Rise

The United States vibratory hammer market is evolving rapidly as demand for sustainable and efficient foundation solutions grows. According to a 2024 Journal of Civil Engineering review, vibratory hammers can reduce pile installation times by up to 30% compared with diesel hammers, making them the preferred choice for urban and marine projects across the U.S.

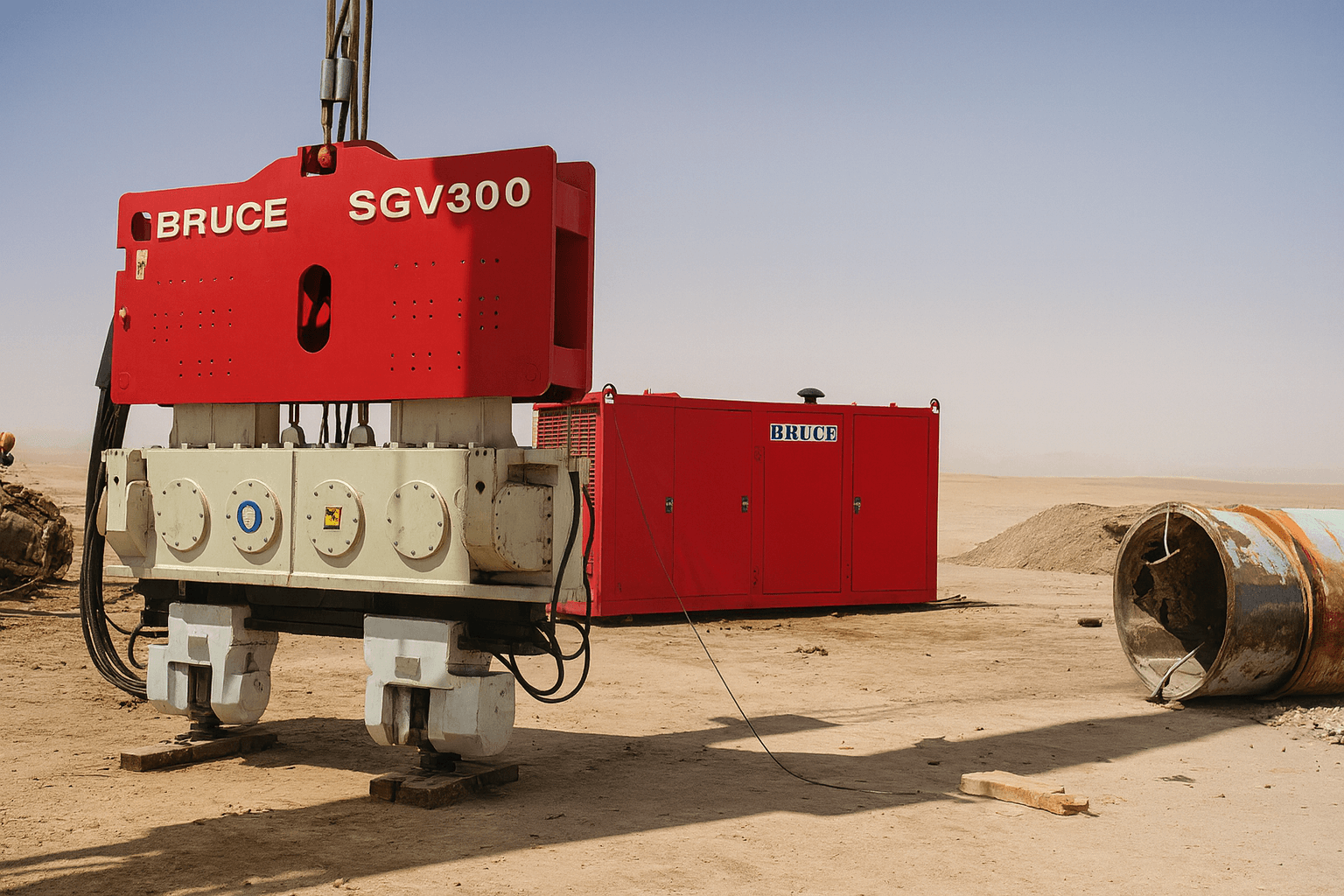

In this context, BRUCE Piling Equipment has strengthened its reputation as a trusted vibro hammer supplier company, delivering reliable solutions to American contractors who prioritize efficiency, compliance, and long-term value.

👉 Explore BRUCE’s vibro hammer features

Market Outlook 2025: Growth Factors in the U.S.

The U.S. market for vibratory hammers is forecast to expand steadily due to:

-

· Federal Infrastructure Investments: Multi-billion-dollar highway, bridge, and port projects drive demand for deep foundation equipment.

-

· Offshore Wind Energy Projects: Vibratory hammers play a critical role in monopile installations along the East Coast.

-

· Urban Construction Regulations: Strict noise and vibration control rules favor modern hydraulic vibro hammers over diesel hammers.

The Federal Highway Administration (FHWA, 2023) highlights vibratory technology as a key enabler for faster and safer piling in constrained urban environments.

Why BRUCE Dominates as a Vibro Hammer Supplier Company

· Proven Technology

BRUCE vibro hammers integrate hydraulic clamps, adjustable frequency control, and high centrifugal force ranges (500–4,600 kN). These features enable smooth pile installation in diverse U.S. soil conditions—from compact clay in Texas to sandy coastal soils in Florida.

👉 Learn more in our technical glossary

· Trusted Reliability

BRUCE equipment has been deployed in U.S. marine bridge foundations, offshore energy platforms, and metropolitan transit projects, consistently meeting environmental and performance standards.

· Performance

Independent research in DTU Offshore Studies (2021) demonstrated that vibration-based hammers with noise-suppression kits reduced sound levels by up to 35% while maintaining penetration speed—aligning with U.S. EPA environmental standards.

Applications in U.S. Projects

· Urban Infrastructure – Subway tunnels, skyscraper foundations, and bridges in major U.S. cities where noise control is critical.

· Marine & Offshore Energy – Offshore wind farms, oil terminals, and port expansions.

· Civil Works – Flood barriers, seawalls, and temporary cofferdams.

👉 Discover more applications in our vibratory hammer blog guide

Benefits for U.S. Contractors

· Efficiency: Up to 40% faster installation cycles compared with impact hammers.

· Compliance: Meets U.S. EPA, OSHA, and marine environmental standards.

· Cost Savings: Reduced downtime and maintenance through robust design.

· Flexibility: Suitable for sheet piles, H-beams, casing piles, and caissons.

👉 Contact our U.S. project team today via Contact BRUCE

Conclusion: United States Market Trends & BRUCE’s Role

The United States vibratory hammer market in 2025 reflects a shift toward cleaner, faster, and safer piling technologies. With decades of proven performance, BRUCE continues to define what it means to be a top-tier vibro hammer supplier company—supporting U.S. contractors with reliable equipment, technical expertise, and ISO-certified quality.

👉 Visit the official BRUCE site for specifications

👉 Follow BRUCE on LinkedIn

👉 Explore real project visuals on Pinterest

📩 For detailed specs and U.S. project support: [email protected]