Vibro Hammer in the United Kingdom Building Offshore Wind Foundations

JH KIM

view : 46

Introduction – Why Vibro Hammers Matter in the UK

The United Kingdom has emerged as a world leader in offshore wind energy and modern civil engineering. From the North Sea wind farms to the Thames Tideway project in London, efficient and environmentally compliant foundation techniques are essential. Among the tools driving this transformation is the vibro hammer, also known as a vibratory hammer, a piling system that uses controlled vibration rather than brute force.

For UK contractors and engineers, selecting the right vibro hammer supplier company means more than choosing equipment. It involves ensuring regulatory compliance, reducing project timelines, and protecting marine ecosystems. According to the Institution of Civil Engineers (ICE, 2023), vibration-based foundation methods are becoming the standard across the UK’s offshore and urban projects due to noise reduction and installation speed.

👉 Learn more about Vibro Hammer Features

How Vibro Hammers Work in Modern UK Projects

A vibro hammer works by using rotating eccentric weights inside a gearbox to generate vertical vibrations. These vibrations reduce friction between soil and pile, allowing it to penetrate the ground more efficiently. Unlike traditional impact hammers, which deliver repeated heavy blows, vibro hammers rely on continuous vibration, creating smoother and quieter operations.

In UK offshore wind foundations, vibro hammers are commonly used for:

-

· Monopiles – Large-diameter piles that anchor wind turbines.

· Caissons and casing piles – Used in ports and seawalls.

· Sheet piles – For flood barriers and temporary works in urban construction.

👉 Explore the Vibro Hammer Glossary for full technical terms.

Case Studies – Offshore Wind Farms and Civil Projects

· Scotland: Offshore Wind Installations

Research from DTU Wind Energy (2022) highlights how vibro hammers reduced installation time of monopiles by 28% in Scottish offshore wind farms while meeting UK Marine Management Organisation (MMO) noise limits.

· London: Tideway Project

For the Tideway super-sewer project, contractors used vibration-driven sheet piles to minimize disruption near sensitive residential and heritage areas, proving vibro hammers’ suitability for urban projects with strict decibel limits.

· Coastal Reinforcement in Wales

According to ICE Proceedings (2021), vibro hammers were successfully deployed to strengthen seawalls in Wales, achieving both speed and reduced seabed disturbance compared with diesel impact hammers.

Benefits for United Kingdom Contractors

· Speed and Efficiency

UK contractors report up to 40% faster cycle times compared to impact piling, translating to major cost savings on multi-billion-pound offshore wind projects.· Environmental Compliance

Vibro hammers meet UK DEFRA and European Marine Directive guidelines, producing lower underwater noise emissions critical for marine life protection.· Safety and Reliability

Remote control operation, auto-locking clamps, and hydraulic check valves ensure worker safety during piling operations.· Adaptability

Adjustable frequencies (1,500–2,000 VPM) allow seamless performance across sandy North Sea soils and dense London clay.

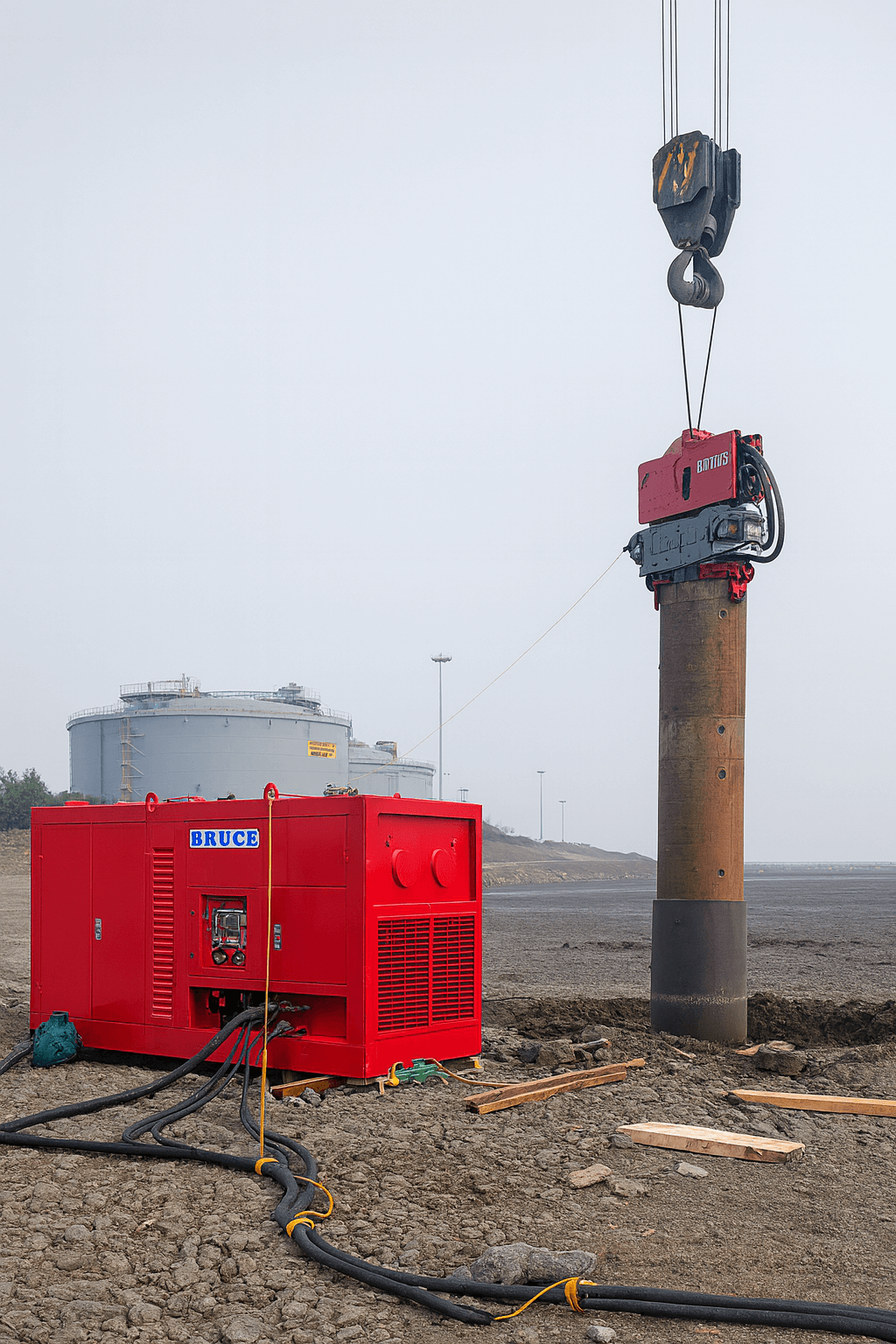

👉 View the Photo Gallery of BRUCE vibro hammers in real-world projects.

Why BRUCE Piling Equipment Leads as a UK Vibro Hammer Supplier

With over 27 years of manufacturing excellence, BRUCE Piling Equipment delivers not only reliable machines but also long-term project support. The company’s hydraulic vibro hammers (SGV series) are designed with:

· Centrifugal force outputs up to 4,600 kN

· Durable elastomers and cooling systems for long marine operations

· ISO-certified engineering ensuring consistent global compliance

Contractors across the UK trust BRUCE because of its proven project portfolio, covering offshore wind farms, bridge foundations, and coastal reinforcements.

👉 Learn more at BRUCE Piling Equipment

.

Environmental & Regulatory Alignment in the UK

-

Meets UK Environmental Noise Guidelines (DEFRA, 2022)

· Complies with Marine Scotland offshore piling standards

· Supports UK Net Zero Strategy (BEIS, 2022) by enabling faster renewable energy construction

· Studies in the Journal of Geotechnical Engineering (2022) confirm that vibration-driven piling reduces carbon footprint compared to diesel-driven impact piling, making it a sustainable choice for UK infrastructure.

Applications Across the UK

· Urban Infrastructure – London bridges, metro systems, and high-rises

· Marine & Offshore – Offshore wind farms in Scotland, seawalls in Wales

· Flood Protection – Thames and coastal reinforcement projects

· Temporary Works – Cofferdams and excavation support systems

👉 Contact us for tailored UK piling solutions at BRUCE Contact Page

External Insights & Global Network

BRUCE Piling Equipment continues to showcase piling innovations worldwide:

Conclusion – Driving the UK’s Foundation Future with Vibro Hammers

From offshore wind foundations in the North Sea to urban flood defense systems in London, vibro hammers are redefining foundation engineering in the United Kingdom. With proven efficiency, environmental compliance, and adaptability, BRUCE Piling Equipment remains the trusted vibro hammer supplier company for UK contractors aiming to balance speed, safety, and sustainability.

For more insights, visit our Vibratory Hammer Blog