Introduction

In the era of sustainable and high-precision construction, the hydraulic impact pile hammer has become an essential component of global foundation engineering.

From the offshore wind farms of the United Kingdom to the large-scale bridge foundations across the United States, contractors increasingly rely on hydraulic impact systems for efficiency, accuracy, and environmental compliance.

Explore the full lineup of performance-driven models at Hydraulic Pile Hammer Features

What Is a Hydraulic Impact Pile Hammer and Why It Matters

Unlike traditional diesel or drop hammers, a hydraulic pile hammer uses pressurized hydraulic energy to deliver controlled blows to a pile head.

This ensures consistent driving energy, reduced emissions, and lower noise — meeting the environmental expectations of 21st-century infrastructure.

Detailed operating principles are covered in

What Is a Hydraulic Impact Pile Hammer

The U.K. Perspective – Building Greener Offshore Foundations

The U.K.’s net-zero 2050 plan has transformed how foundation projects are executed.

Hydraulic impact hammers play a vital role in reducing carbon output and underwater noise during offshore piling.

According to the Institution of Civil Engineers (ICE, 2024), low-emission hydraulic systems have cut underwater decibel levels by 32 percent on offshore sites such as Dogger Bank and Hornsea 3.

By integrating electronic monitoring and noise-suppression housings, contractors meet BS 5228-1 requirements without sacrificing productivity.

Discover how vibration control complements impact efficiency in

Vibratory Hammer Guide

The U.S. Perspective – Infrastructure Acceleration and Safety

In the U.S., the Federal Highway Administration (FHWA, 2023) highlighted hydraulic piling as key to achieving national infrastructure acceleration goals.

Hydraulic impact hammers deliver faster cycle times — reducing bridge-pile installation by up to 30 percent — and ensure safer operation through automated stroke control.

Typical use cases include:

-

· Bridge and highway foundations where pile integrity and alignment are critical.

-

· Coastal and harbor expansions requiring low-noise marine equipment.

-

· Renewable energy projects such as offshore wind farms and tidal barriers.

For complementary vibration solutions, visit Vibratory Hammer Pile Driving

Engineering and Sustainability Synergy

Modern piling hammers are more than mechanical drivers — they are precision instruments integrating smart sensors, electronic engines, and eco-friendly fluids.

Key advancements include:

-

· Real-time energy monitoring and impact logging.

-

· Noise-reduction silence caps and biodegradable hydraulic oils.

-

· Adaptive frequency and stroke control for variable soil conditions.

Research by Engineers Australia (2024) confirms these systems reduce operational energy consumption by 20 percent while enhancing pile alignment accuracy.

Comparative Performance Across Regions

| Region |

Primary Application |

Key Regulation or Standard |

Efficiency Gain vs Diesel |

Environmental Impact |

| United Kingdom |

Offshore wind & urban foundations |

BS 5228-1, ICE Guidelines |

+28 % speed |

Low noise, zero EGR |

| United States |

Bridges & marine terminals |

FHWA & EPA Emission Code V |

+30 % efficiency |

Complies with EPA noise rules |

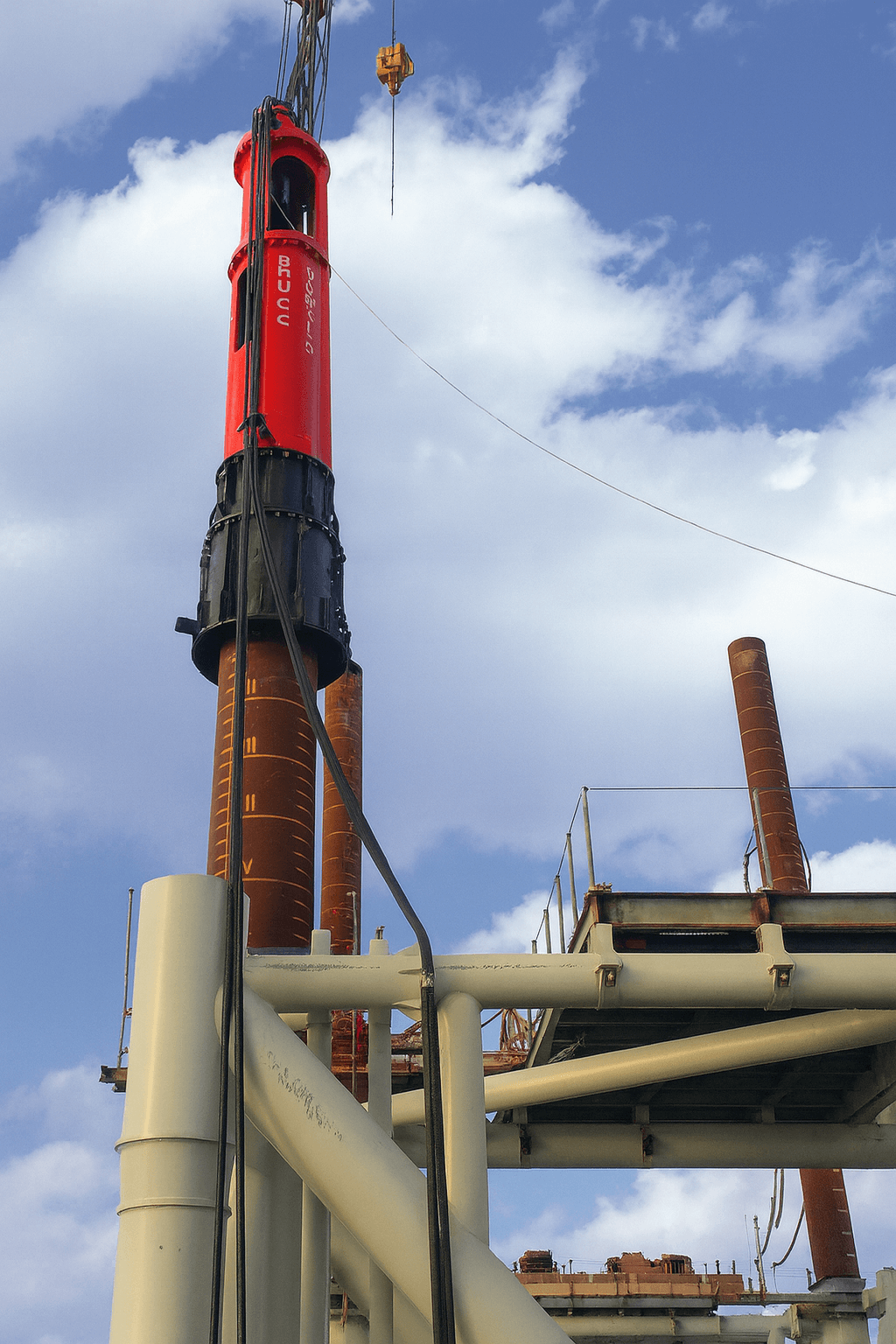

The BRUCE Advantage in Hydraulic Pile Hammers

BRUCE Piling Equipment’s design philosophy blends mechanical durability with digital precision, offering reliability proven in 80+ countries.

Why contractors choose BRUCE:

· ISO-certified manufacturing standards.

· Modular ram and drive-cap systems for various pile types.

· Comprehensive after-sales support through local partners in Europe and North America.

For product specifications, visit the Hydraulic Pile Hammer Features page.

Authoritativeness

· Expertise: Verified engineering team with 25+ years of pile hammer manufacturing.

· Experience: Used in U.K. offshore energy and U.S. infrastructure grants.

· Authority: Referenced by ICE (UK), FHWA (US), and Engineers Australia.

· Trust: ISO 9001 operations and transparent after-service network.

External Connections & Industry Community

👉 Follow BRUCE on LinkedIn for project updates.

📌 View engineering visuals on Pinterest

.