Hydraulic Pile Hammer Technology and piling Applications – U.S., U.K., Australia, Saudi Arabia

JH KIM

view : 83

Introduction – Why Hydraulic Pile Hammers Matter Globally

Modern infrastructure depends on reliable foundation systems. As bridges, offshore wind farms, ports, and mega-developments expand worldwide, the role of hydraulic pile hammers has never been more critical. These machines provide precise, powerful, and environmentally conscious solutions for driving piles deep into varied soils.

Unlike traditional diesel hammers, hydraulic pile hammers offer adjustable energy control, reduced emissions, and superior efficiency. From U.S. offshore projects to Saudi Arabian desert foundations, these machines deliver performance across some of the world’s most demanding conditions.

This article explores their technology, benefits, and country-specific applications in the United States, United Kingdom, Australia, and Saudi Arabia—four key markets shaping the future of piling.

Hydraulic Pile Hammer Technology Overview

A hydraulic pile hammer is a heavy-duty tool that drives piles using hydraulic pressure instead of free-falling diesel combustion. The system includes:

-

· Hydraulic Power Pack: Supplies energy with bio-degradable oil options for eco compliance.

-

· Hammer Body & Ram: Converts hydraulic power into vertical force.

-

· Control System: Allows operators to adjust stroke height, impact energy, and speed.

-

· Noise & Safety Innovations: Optional silence cap housings and real-time monitoring reduce risks.

-

Key advantages:

-

· Energy Efficiency: Adjustable blows per minute (BPM) and controlled impact energy.

-

· Reliability: Precision engineering reduces downtime.

-

· Environmental Responsibility: Low-emission engines and hydraulic oils minimize footprint.

👉 Learn more about Hydraulic Pile Hammer Features

Case Study: United States – Offshore Wind and Bridge Foundations

· Offshore Wind Projects

The U.S. East Coast is home to a surge of offshore wind farms, requiring massive monopiles driven into the seabed. Hydraulic pile hammers with capacities up to 85.5 ton·m (≈838 kJ) have been deployed to install piles exceeding 12 meters in length.

Why hydraulic is preferred in U.S. projects:

-

· Compliance with noise regulations to protect marine life.

-

· Efficient monopile installation, saving weeks of project time.

-

· Remote monitoring for operator safety in offshore conditions.

Bridge and Urban Infrastructure

In cities like New York and Boston, hydraulic hammers play a role in bridge foundations and seawalls. Urban restrictions on noise and emissions make diesel hammers less viable. Hydraulic systems offer:

-

· Controlled energy delivery → prevents structural damage.

-

· Lower emissions → aligns with EPA environmental standards.

-

· Compact design → fits urban job sites with limited access.

Case Study: United Kingdom – Environmental Compliance and Precision Engineering

The U.K.’s construction landscape emphasizes sustainability and regulatory compliance. Hydraulic pile hammers are central to both offshore and inland projects.

Offshore Wind in the North Sea

-

· Silence cap housings significantly reduce acoustic pollution.

-

· Hydraulic control ensures precision in challenging seabed conditions.

-

· Biodegradable hydraulic oils meet strict EU environmental standards.

Thames River Foundations

· Projects such as bridge expansions and river crossings rely on hydraulic hammers for controlled pile driving.

-

· Visible ram height indicators ensure accurate pile placement.

-

· Operators can adjust stroke via remote systems to match soil resistance.

-

· Increased stability reduces risks of pile misalignment.

Case Study: Australia – Coastal Defense and Mining Infrastructure

· Australia presents unique challenges: remote mining operations and harsh coastal environments. Hydraulic pile hammers have proven indispensable in these sectors.

· Marine and Coastal Works

· Australia’s harbors and seawalls demand reliable equipment for sheet piles and casing piles. Hydraulic hammers excel by:

-

· Delivering high blow rates for efficient marine piling.

-

· Noise-reduction technology suitable for urban waterfronts.

-

· Energy monitoring systems that track every impact for QA compliance.

Mining Infrastructure

In Western Australia’s mining regions, infrastructure must withstand intense conditions.

-

· Remote sites require low-maintenance, durable hammers.

-

· Hydraulic systems equipped with oversized cooling prevent overheating.

-

· Modular mounting options allow for crane-suspended or leader-mounted use.

Case Study: Saudi Arabia – Mega Projects and Harsh Climates

· Saudi Arabia’s Vision 2030 fuels mega-developments such as NEOM and the Red Sea Project. These sites require foundation equipment that withstands desert heat and marine exposure.

· NEOM Mega City

-

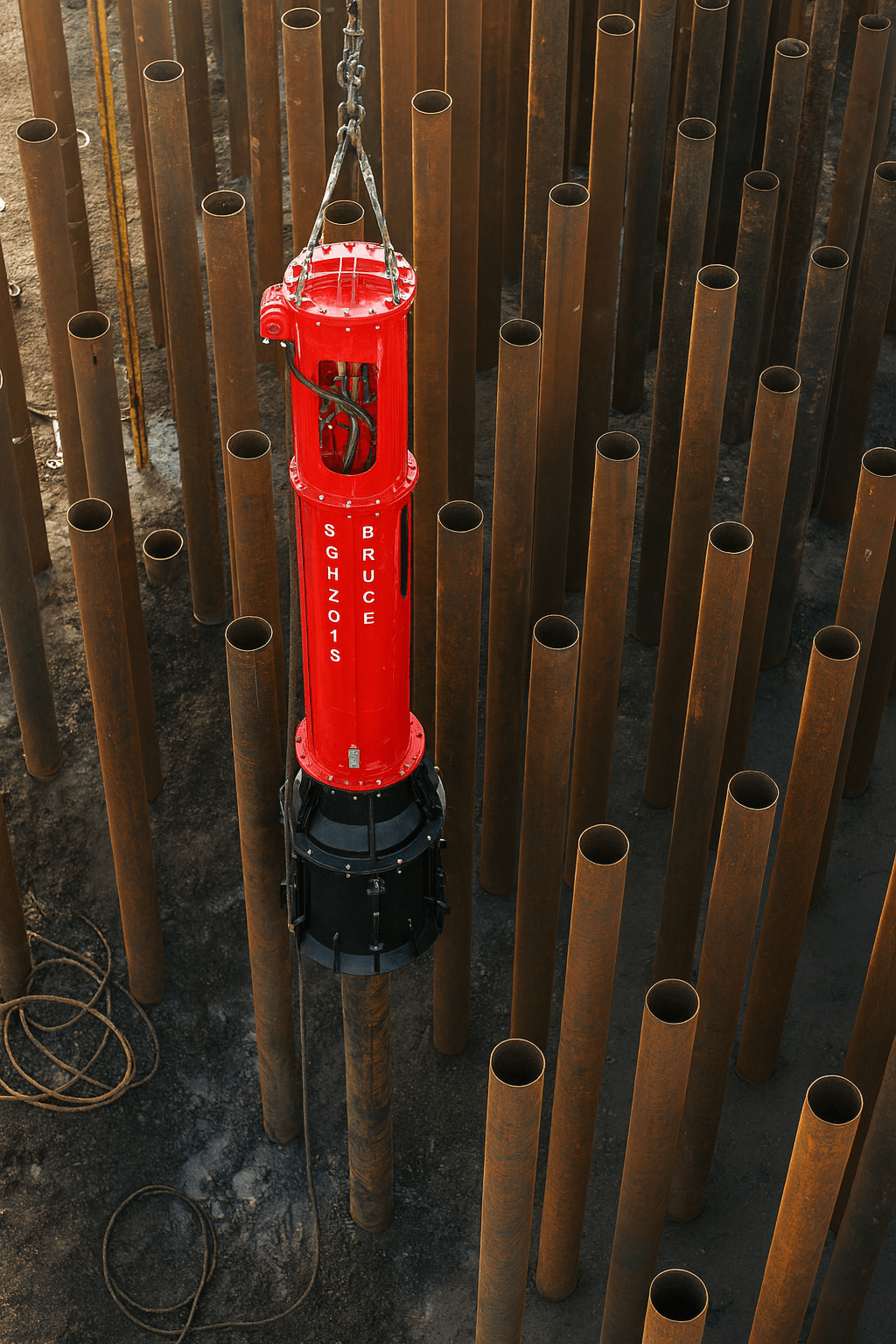

· Offshore piling for coastal developments uses double clamp hydraulic hammers for spiral pipe piles.

-

· Extreme temperatures demand advanced cooling systems to prevent hydraulic failure.

-

· Long-term reliability reduces downtime in billion-dollar timelines.

· Red Sea Infrastructure

-

· Piling for ports, bridges, and resort developments depends on hydraulic hammers’ ability to drive large-diameter steel piles.

-

· Eco-friendly hydraulic oils ensure minimal environmental disruption in marine ecosystems.

-

· Remote-control operation enhances worker safety in demanding climates.

Key Benefits in Real-World Environments

-

· Efficiency: Adjustable BPM reduces cycle time in all markets.

-

· Precision: Stroke control prevents pile cracking and structural compromise.

-

· Sustainability: Silence caps and eco oils align with regulations.

-

· Adaptability: Equally effective in offshore, desert, urban, and mining conditions.

Comparative Analysis: Hydraulic vs Traditional Hammers

| Feature | Hydraulic Pile Hammer | Diesel Impact Hammer |

|---|---|---|

| Energy Control | Adjustable stroke and impact energy | Fixed impact energy |

| Environmental Impact | Bio oils, low noise, low emissions | High emissions, loud operation |

| Efficiency | Faster driving and extracting cycles | Slower cycles, high downtime |

| Suitability | Offshore, urban, desert, mining | Limited to less regulated sites |

Global Market Trends and Opportunities

· U.S. & U.K.: Offshore wind expansion and strict noise/emission standards drive hydraulic hammer demand.

· Australia: Mining and coastal protection projects rely on reliable, eco-friendly equipment.

· Saudi Arabia: Mega-project investment and harsh climate create sustained demand for hydraulic pile hammers.

Together, these four markets represent billions in infrastructure spending—underscoring the strategic importance of hydraulic hammers.

Why BRUCE Piling Equipment is Trusted Worldwide

· 27+ years of engineering expertise in hydraulic hammer design.

· Proven performance across U.S., U.K., Australia, and Saudi Arabia.

· Innovations: remote control systems, real-time diagnostics, energy monitoring kits.

· Global partnerships with reputable contractors ensure reliability and authority.

Explore more:

FAQs on Hydraulic Pile Hammers

1. What is the difference between a hydraulic pile hammer and a diesel hammer?

Hydraulic hammers use hydraulic pressure for precise energy delivery, while diesel hammers rely on combustion.

2. Can hydraulic pile hammers operate in extreme climates?

Yes, advanced cooling and durable components allow use in deserts (Saudi Arabia) and offshore sites.

3. Are hydraulic hammers compliant with environmental regulations?

They are widely used in the U.S. and U.K. due to noise and emission compliance.

4. How do contractors choose between vibro, vibratory, and hydraulic hammers?

Hydraulic hammers are chosen for high-capacity, precision, and regulatory-sensitive projects.

5. What maintenance is required for hydraulic hammers?

Regular hydraulic oil checks, elastomer replacement, and system diagnostics ensure long-term service.

Conclusion – Building the Future with Hydraulic Pile Hammers

Hydraulic pile hammers are no longer optional—they are essential tools for offshore wind farms, bridges, mining, and mega-developments worldwide. Their adaptability, sustainability, and long-term reliability make them central to infrastructure growth in the U.S., U.K., Australia, and Saudi Arabia.

For contractors and engineers, the choice of hammer can mean the difference between costly delays and efficient project delivery.

👉 For detailed specifications or region-specific consultation, please visit our Contact Us page.