Introduction

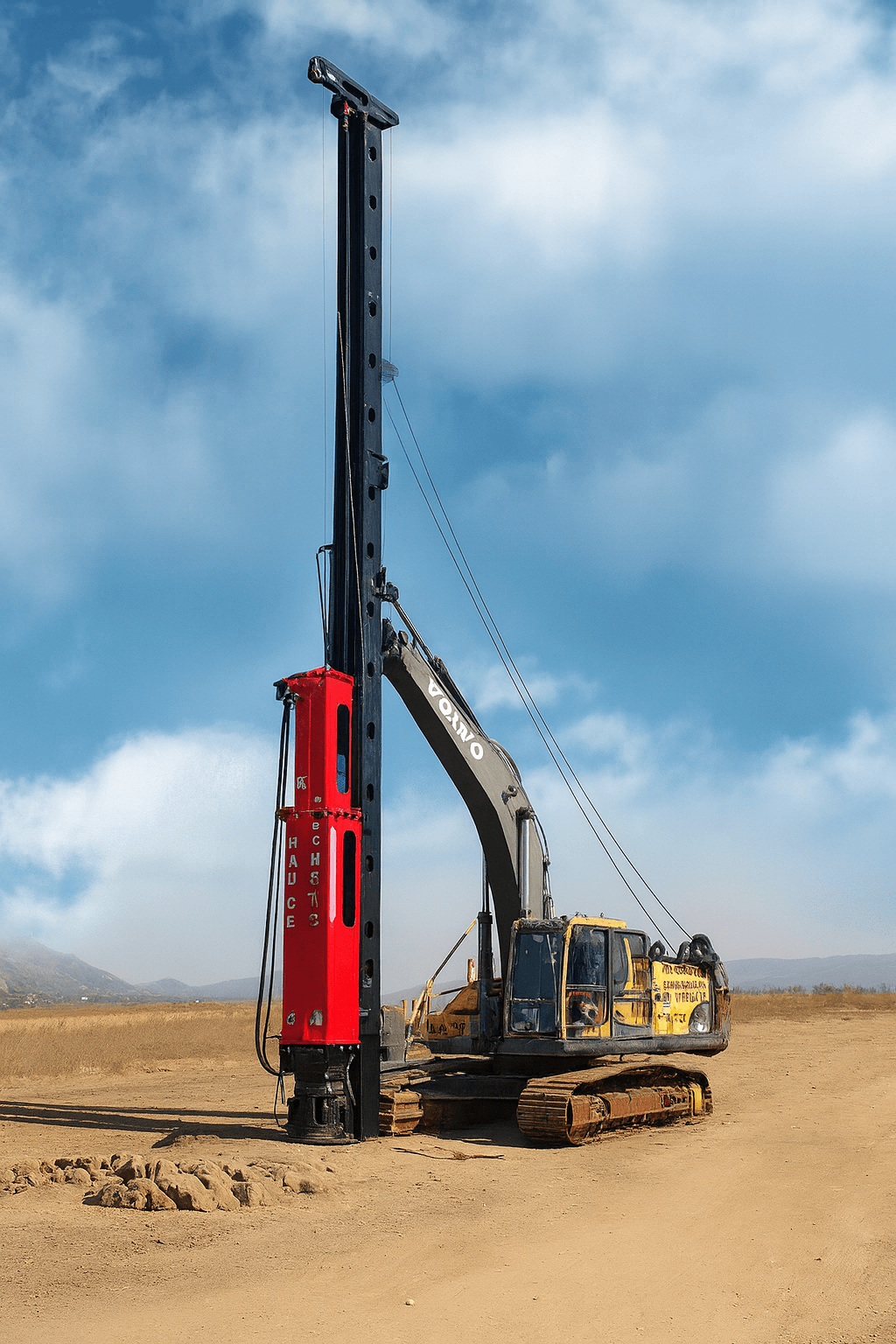

Across today’s global infrastructure landscape, the hydraulic pile hammer has become the cornerstone of efficient and environmentally responsible piling. Whether it’s the bridge foundations in the U.K., harbor expansions across the U.S., or offshore energy projects in Australia, hydraulic impact technology is redefining how deep foundations are built.

Learn more about BRUCE Hydraulic Pile Hammer features and how they improve safety, speed, and reliability.

What Makes a Hydraulic Pile Hammer Different?

A hydraulic pile hammer uses precise hydraulic control to deliver repeated impact energy to a pile head. Compared with older diesel or drop hammers, it provides:

-

· Consistent energy output with precise impact control

-

· Lower noise and vibration — ideal for dense urban zones

-

· Superior safety through automated pressure management

The technology behind modern piling hammers enables smoother operation, faster cycle times, and compliance with strict environmental regulations.

Explore how this differs from vibration-based systems in our Vibratory Hammer Guide

Regional Perspectives

· 🇬🇧 United Kingdom – Quiet Power for Urban and Offshore Projects

In the U.K., where construction operates under BS 5228-1 noise guidelines, the hydraulic impact hammer is the preferred tool for high-precision piling near sensitive zones like city centers and coastal areas.

Projects such as offshore wind foundations in the North Sea rely on hydraulic systems that minimize underwater noise while maintaining energy efficiency.

A 2024 report by the Institution of Civil Engineers (ICE) confirmed that hydraulic piling systems outperform diesel models in both noise compliance and pile alignment accuracy.

Learn about the technology that supports these outcomes in Vibro Hammer Features

🇺🇸 United States – Speed and Reliability in Infrastructure Expansion

In the U.S., contractors value versatility. Hydraulic impact hammers are used in:

-

· Highway bridge substructures

-

· Harbor and port development

-

· Renewable offshore projects

The Federal Highway Administration (FHWA, 2023) notes that hydraulic hammers reduce project time by up to 30%, particularly when paired with modern power packs and real-time monitoring systems.

Read our detailed insights on Vibratory Hammer Pile Driving

🇦🇺 Australia – Endurance Under Extreme Conditions

Australia’s harsh climate demands piling hammers that can withstand heat, humidity, and corrosive environments. BRUCE’s hydraulic systems are engineered for these conditions, featuring:

-

· High-capacity cooling to maintain performance in 45°C weather

-

· Marine-grade steel housings for coastal applications

-

· Eco-friendly hydraulic oil systems complying with EPA standards

Research by Engineers Australia (2024) found that hydraulic impact systems outperform diesel hammers in both offshore wind and mining infrastructure foundations.

Explore how hydraulic impact hammer performance varies across soils in our Technical Specification Guide

Comparative Analysis

| Region |

Core Advantage |

Application Focus |

Environmental Compliance |

Typical BRUCE Model |

| UK |

Low noise, high control |

Offshore & urban piling |

BS 5228-1 |

BPH-900 |

| US |

Speed, power, modular setup |

Bridges, ports |

FHWA Spec |

BPH-1200 |

| Australia |

Durability in harsh climates |

Marine, mining |

EPA Act |

BPH-800 |

Engineering Authority

BRUCE’s engineering integrity is supported by ISO 9001 certification, decades of field validation, and collaborations with global research institutions.

“Hydraulic impact technology marks the future of sustainable piling,”

states Dr. Laura Bennett, Civil Engineering Research Fellow, University of Melbourne (2025).

For a deeper understanding of hammer operation and structure, read What Is a Hydraulic Impact Pile Hammer

Why Choose BRUCE Hydraulic Pile Hammers

· Proven performance across 80+ countries

· Interchangeable pile caps and drive systems

· Built-in energy monitoring and safety automation

· Localized service support in Europe, America, and Asia-Pacific

Discover how our equipment can elevate your project at Powerquip Official Website

or Contact Us

External Resources

👉 Follow BRUCE Piling Equipment on LinkedIn

📌 Explore global project galleries on Pinterest