In sheet pile driving, the difference between profit and loss often comes down to one decision: Equipment Selection.

Choosing the wrong excavator-mounted vibro hammer can lead to disastrous consequences—piles refusing to penetrate, excessive vibration damaging nearby structures, or your excavator’s hydraulic pump overheating.

Many contractors make the mistake of choosing a hammer based solely on “Price” or “Total Weight.” However, to drive piles successfully in diverse soil conditions, you must understand the physics behind the machine.

This comprehensive guide, written by the engineering team at BRUCE (PowerQuip), will walk you through the technical specs that actually matter and how to request a price quote to get the most accurate proposal.

1. Deep Dive: Technical Specs You Must Understand

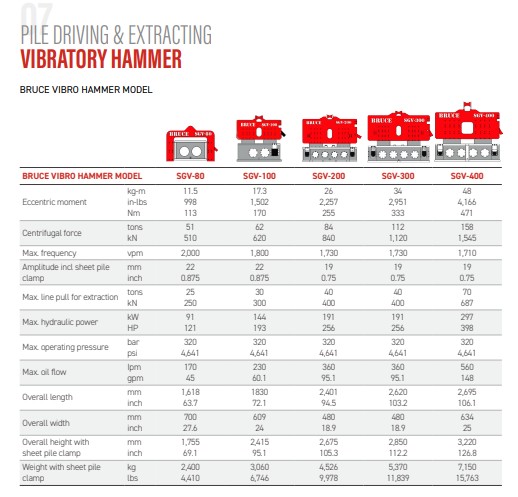

When reading a datasheet, do not just glance at the numbers. You need to interpret what they mean for your job site.

A. Eccentric Moment (kgm): The Muscle

This is the single most important specification. It creates the amplitude necessary to break the soil’s friction.

-

The Engineering Reality: Heavier piles and stiffer soils (Clay/Hardpan) require a higher eccentric moment. If this value is too low, the hammer will just vibrate on top of the pile without driving it down.

The BRUCE Advantage: Our SGV Series features a high-density tungsten layout, providing 20-30% higher eccentric moment than competitors in the same weight class.

B. Centrifugal Force & Frequency

High frequency is essential for minimizing ground vibration in urban areas. Our SGV series is optimized to handle both standard and high-frequency requirements effectively.

📥 Want to compare all models at a glance? Download our official brochure to see the detailed spec table for every SGV model. 👉 [Click to Download BRUCE General Brochure & Catalogue](https://www.powerquip.co.kr/technical/brochure-catalogue-2/)

2. Matching the Hammer to Your Excavator (Crucial)

A common misconception is that “Bigger is Better.” In hydraulic attachments, “Balanced” is Better.

Hydraulic Flow (LPM) & Pressure (Bar)

Your excavator acts as the power pack.

-

If the hammer demands 240 LPM but your excavator only pumps 200 LPM, the hammer will run slow.

-

If your excavator pumps 300 LPM without a proper flow control valve, you risk blowing the hammer’s motor seals.

BRUCE Compatibility Check: We customize the flow settings for all major brands. Whether you run a CAT 336, Volvo EC480, or Hyundai HX series, we configure the motor displacement to match your base machine perfectly.

3. Operational Efficiency & Maintenance Costs

Smart buyers look at the Total Cost of Ownership (TCO), not just the initial purchase price.

-

360-degree Rotation & 90-degree Tilting: Allows picking up piles directly from the ground, reducing labor costs.

-

Elastomer Durability: BRUCE uses premium-grade elastomers that last significantly longer, reducing downtime.

-

Parts Availability: We use global standard components (e.g., Parker motors, SKF bearings) for easy maintenance.

4. How to Request a Proper Quote (To Get the Best Deal)

To get a precise commercial offer and avoid back-and-forth emails, please provide the following details in your initial inquiry.

Copy and paste this checklist into your email:

-

Base Machine Info: Brand, Model, and Year (e.g., Doosan DX300LC-5).

-

Target Application: Sheet Piles (Type/Length) or H-Beams.

-

Soil Condition: Sand, Clay, or Rock (N-Value).

-

Project Location: For CIF shipping calculation.

5. Why Global Contractors Switch to BRUCE (PowerQuip)

Since 1998, BRUCE Piling Equipment has focused on one thing: “Driving Power per Dollar.”

-

Performance: Matches European specs.

-

Reliability: Made in Korea (ISO 9001).

-

Price: Highly competitive for faster ROI.

6. Ready to Start Your Project?

Do not leave your project success to chance. Check our full catalog or contact our experts for a customized quote.

📩 Contact Us & Resources: