The Ultimate Guide to Vibratory Hammer – Selection, Price, and Efficiency (2026 Edition)

JH KIM

view : 15

What is a Vibratory Hammer? How do you choose the right one for your excavator?

And is it better to buy New or Used?

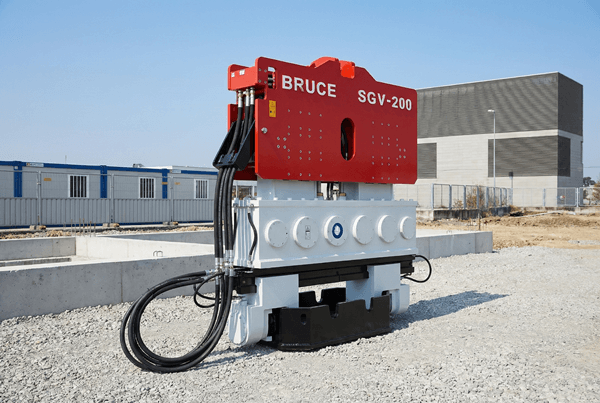

Powerquip (BRUCE) answers the critical questions for contractors in the US, UK, and beyond.

1. Introduction: More Than Just “Shaking the Ground”

If you are reading this, you likely have a piling project coming up. You might be looking to drive Sheet Piles for a cofferdam in Texas, or placing H-Beams for a foundation in London.

You know you need a Vibratory Hammer (also called a Vibro Driver). But the market is confusing. European brands are overpriced. Chinese brands are risky. Used equipment is a gamble.

At Powerquip (BRUCE), we don’t just manufacture equipment; we solve piling problems. This guide is written by our engineering team to help you understand exactly what you are buying, avoiding the marketing fluff and focusing on the physics and financials of pile driving.

2. What is a Vibratory Hammer? (The Technical Definition)

For those new to the industry, let’s define the tool clearly.

A Vibratory Hammer is a hydraulic attachment mounted on an excavator (replacing the bucket). It drives piles into the ground not by hitting them, but by liquefying the soil.

The Mechanism:

Inside the main body, eccentric weights spin at high speeds. This creates vertical vibrations that are transferred to the pile via hydraulic jaws. These vibrations reduce the friction between the pile and the soil, allowing the pile to sink under its own weight and the down-force of the excavator.

Engineering Note: The key metric is not just “weight.” It is the Eccentric Moment (kgm / in-lbs) and Frequency (rpm). A higher frequency is crucial for minimizing ground resonance, which is required for urban projects near existing buildings.

For a deeper dive into the physics of liquefaction, read our engineer’s analysis here:

👉Understanding Vibratory Hammer Pile Driving Principles

3. Comparison: Tilting vs. Standard (Fixed) Type

One of the most common questions we get is: “Do I need a Tilting Hammer?”

Here is the honest breakdown based on job site efficiency.

Standard Type (Fixed)

· Pros: Lower initial cost, simple mechanics, very powerful driving force.

· Cons: You cannot pick up a pile lying on the ground. You need a separate crane or a ground worker to chain the pile and lift it to a vertical position.

· Best For: Open fields where you have support cranes available.

Tilting Type (90-Degree Rotation)

· Pros: The hammer can tilt 90 degrees to grab a pile directly from the ground and lift it upright.

· Cons: Higher initial investment.

· Best For: Urban sites, limited spaces, or projects where you want to reduce labor costs (no need for a “chain man”).

Comparison Table: ROI Analysis

| Feature | Standard (Fixed) | Powerquip Tilting (SGH-T) |

| Pile Handling | Manual / Crane assist required | Auto-pickup (1 Operator) |

| Safety Risk | High (Man under load) | Low (Cab operation) |

| Cycle Time | Slower | 30-40% Faster |

| Maintenance | Low | Low (Patented design) |

See the detailed specs and tilting mechanism in our features section:

👉 View Features & Safety Systems

4. Buying Guide: Matching the Hammer to Your Excavator

Don’t buy a hammer just because it’s cheap. If it’s too small, it won’t drive the pile. If it’s too big, it might damage your excavator’s boom.

We design our hammers to be “Plug & Play” for major Western excavator brands.

20-25 Ton Excavators (e.g., CAT 320, John Deere 210G):

Ideal for: Shorter Sheet Piles (Type 2/3), H-Beams up to 10 meters.

Recommended Powerquip Model: SGH-0415 series.

30-35 Ton Excavators (e.g., CAT 336, Volvo EC300):

The “All-Rounder.” Handles standard Sheet Piles (Type 3/4) and H-Beams in stiff clay.

40-50 Ton Excavators (e.g., John Deere 470G, Case CX490):

Heavy Duty. Capable of driving long piles (15m+) into hard soil conditions.

Note: We provide custom mounting brackets and pins for Caterpillar, John Deere, Case, Volvo, Hitachi, and JCB.

5. Material Matters: Why We Use Hardox® Steel

In the US and UK markets, durability is the #1 requirement. A hammer that cracks after 6 months is useless.

Many low-cost competitors use standard mild steel (A36) for the hammer body. This is why their units are cheap—and why they fail.

Powerquip (BRUCE) uses Hardox® Wear Plate.

Hardox is a specialized Swedish steel known for extreme toughness. By using this in our hammer bodies and jaws, we ensure that our equipment can withstand the intense vibration and heat generated during pile driving.

We connect with foundation professionals globally to share these quality standards.

👉 Join our Professional Network on LinkedIn

6. New vs. Used: The “Factory Direct” Advantage

This is the financial part. Contractors often search for “Used Vibratory Hammer for Sale” hoping to save money.

The Hidden Risks of Used Equipment:

· Worn Elastomers: Replacing a full set of rubber buffers costs thousands of dollars.

· Motor Life: You don’t know if the previous owner overheated the hydraulic motor.

· No Warranty: Once it breaks, you are on your own.

The Powerquip Alternative:

Because we are the Manufacturer (not a dealer), we can offer Brand New 2026 Models at prices that compete with used dealer inventory. You get a new machine, a 1-year warranty, and direct parts support from Korea.

Check our Job Site Gallery to see our new units in action:

👉 View Project References on Pinterest

7. Frequently Asked Questions (FAQ)

Q: Can I install this hammer myself?

A: Yes. We supply a complete installation kit including hydraulic hoses, a flow control valve, and a joystick pedal. Any competent heavy equipment mechanic can install it in 4-6 hours.

Q: Do you ship to the USA and UK?

A: Absolutely. We ship DDP or CIF to major ports like Houston, Los Angeles, New York, Southampton, and Felixstowe. We handle the export crate packing to ensure it arrives safely.

Q: How do I get a price list?

A: Prices vary by excavator size and options. Please download our brochure to identify your needs, then contact us for a quote.

👉 Download 2026 Digital Brochure & Catalogue

8. Conclusion: Stop Guessing, Start Driving.

Your project timeline doesn’t have room for equipment failure. Choose a Vibratory Hammer engineered for durability and supported by the manufacturer.

Get a Factory Direct Quote Today.

Contact Powerquip (BRUCE):

Website: www.powerquip.co.kr

Email: [email protected]

Sales Requirement: Please include your Excavator Model and Target Soil Condition for the most accurate recommendation.