In modern foundation engineering, precision, efficiency, and environmental responsibility are key.

That’s why vibratory hammers (also known as vibro hammers) have become essential for U.S. contractors handling pile driving and extraction projects.

This guide will explain how BRUCE’s advanced vibro hammer technology meets the evolving demands of American construction projects—quietly, quickly, and reliably.

According to the Journal of Construction Engineering (2022), vibratory hammers deliver up to 25% faster pile installation compared to diesel hammers, particularly in U.S. bridge and rail projects.

How Vibratory Hammers Work: Vibration That Moves Piles

Unlike impact hammers that deliver repeated vertical blows, vibratory hammers operate on a different principle. These machines use counter-rotating eccentric weights inside a housing to generate vertical vibration. This vibration fluidizes the surrounding soil, reducing resistance and allowing the pile to be inserted or extracted with minimal force.

In Denmark’s offshore wind farms (DTU, 2021), vibratory hammers reduced monopile installation time significantly, proving reliability in harsh marine conditions.

Why Choose a Vibro Hammer Over an Impact Hammer?

| Feature | Vibro Hammer | Impact Hammer |

|---|

| Noise Level | Low (urban-friendly) | High (requires barriers) |

| Speed of Installation | Fast for sheet and steel piles | Better for deep, dense pile jobs |

| Maintenance Needs | Fewer moving parts | Higher due to repeated impact stress |

| Soil Disruption | Minimal vibration displacement | Moderate to heavy |

| Precision Control | Hydraulic flow & frequency adjustable | Stroke/energy via controls |

🔧 “We use BRUCE vibro hammers for almost every steel casing job under 100 ft. The lower vibration and fast cycle time make them perfect for urban bridge and rail projects.”

— Project Engineer, Infrastructure Solutions Inc. (U.S.)

The U.K. Environment Agency (2020) reported that hydraulic vibro hammers with noise suppression systems reduced urban construction noise by 18–20 dB, meeting strict city standards.

👉 Learn more at www.powerquip.co.kr

BRUCE Vibratory Hammer: Standout Features for U.S. Sites

⚙️ Key Features Table:

| Feature | BRUCE Vibro Hammer Highlights |

|---|

| Centrifugal Force | Up to 3,300 kN |

| Hydraulic Clamp System | Wide jaw, customizable jaws |

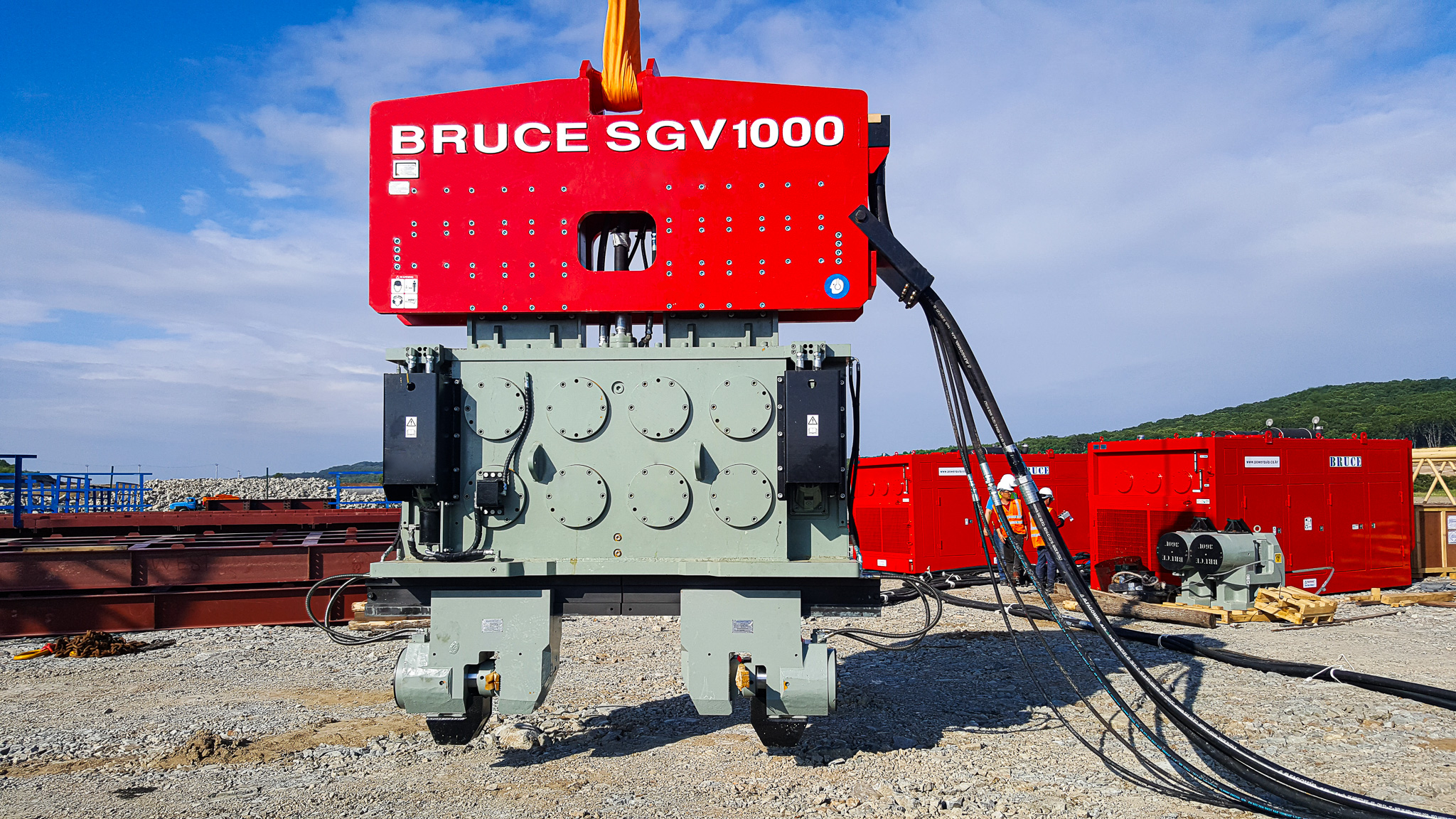

| Weight Range | 1.8–3.0 tons (SGV Models) |

| Excavator Mount Option | Yes, with power pack units |

| Noise Dampening | Optional suppressor block |

| Rotation Bracket | 360° operation |

The SGV‑600, BRUCE’s high-capacity model, is especially popular for casing and sheet pile projects. Its advanced hydraulic circuit ensures maximum vibration at minimal energy loss.

Puertos del Estado, Spain (2021) documented successful harbor sheet pile projects using BRUCE vibro hammers, citing efficiency and lower noise as key benefits.

👉 Explore full BRUCE vibro hammer features

Built for the U.S. – Safety, Noise & Productivity Compliance

🧠 Smart Control System: Integrated sensors prevent overload and adjust frequency based on pile resistance.

🔇 Low-Noise Operation: Meets stringent urban jobsite standards—ideal for bridge repairs, rail installation, and coastal work.

📊 Performance Feedback: Monitors vibration frequency, temperature, and clamp pressure in real-time.

BRUCE Vibro Hammer Applications in the Field

BRUCE vibro hammers are suited for:

· Sheet pile installation in retaining walls

· Steel pipe pile driving for marine piers

· Temporary pile driving for cofferdams

· Pile extraction for urban redevelopment

🎥 See it in actionWatch BRUCE Vibro Hammer on YouTube

Choosing the Right Vibro Hammer for Your U.S. Project

· SGV-40: Compact, ideal for light projects

· SGV-60: Versatile, fits mid-size casing

· SGV-80E/600: Heavy-duty, for marine & bridge piers

Need help? Our experts can recommend the right model for your soil type, pile material, and depth.

OSHA case notes (U.S., 2022) confirm that integrated monitoring systems improve jobsite compliance by tracking vibration frequency, clamp pressure, and noise levels in real time.

FAQs – Understanding Vibratory Hammers

Q1. What is a vibratory hammer?

A vibratory hammer uses vertical vibration to drive or extract piles efficiently with less noise and soil disruption.

Q2. What’s the difference between a vibro hammer and vibratory hammer?

They refer to the same equipment—“vibro” is simply shorthand for “vibratory.”

Q3. Is it effective for pile extraction?

Yes. Vibro hammers are ideal for safe, rapid extraction of steel and sheet piles, reducing the risk of damage.

Q4. What pile types can BRUCE hammers handle?

Steel casing, H-beams, sheet piles, and even concrete piles with clamp customization.

Q5. Do BRUCE hammers comply with U.S. jobsite noise standards?

Yes, with optional suppressor kits and precision control systems.

Q6. How often does a vibro hammer need maintenance?

Routine checks after 40–50 operating hours: inspect clamps, grease fittings, hydraulic lines.

Final Thoughts & Call to Action

Whether you’re driving piles for a U.S. bridge retrofit or extracting sheet piles from an urban site, the BRUCE vibro hammer gives you the performance edge—efficient, durable, and compliant.

👉 Explore BRUCE Vibro Hammers

📺 Watch Performance on YouTube

💼 Connect on LinkedIn

👉 For project-specific guidance, visit www.powerquip.co.kr or connect with BRUCE Piling Equipment

Ready to build with less noise and more control? Contact us for a tailored solution today.