“Vibro hammer company” BRUCE has earned its reputation by delivering unmatched technical precision, reliability, and responsiveness to U.S. marine and metropolitan construction demands. With meticulous engineering, worldwide compliance, and a legacy of over 80 countries served, BRUCE stands as the trusted benchmark in vibro hammer solutions.

According to the U.S. Federal Highway Administration (FHWA, 2022), vibratory hammers have become the preferred choice for marine bridge and port projects due to efficiency and reduced noise levels. Similarly, the U.K. Institution of Civil Engineers (ICE, 2021) highlights their critical role in minimizing disruption in metropolitan piling works.

👉 Visit www.powerquip.co.kr for BRUCE product details.

1. Unrivaled Technical Expertise & Innovation

-

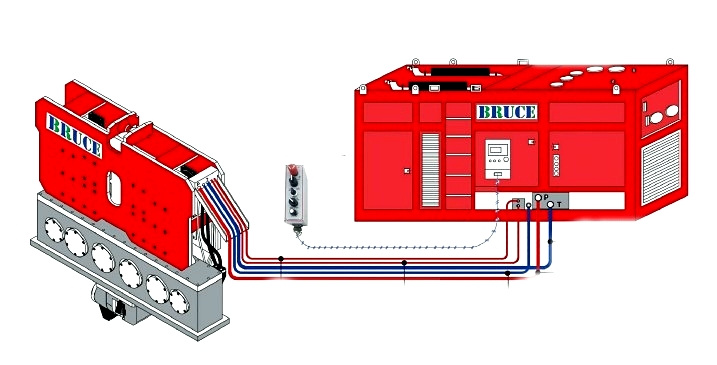

BRUCE’s hydraulic vibratory hammers incorporate high-quality elastomer buffers, remote control pendants with LED diagnostics, and balanced eccentric weights—designed for adaptability to U.S. jobsite conditions.

-

The SGV series delivers adjustable vibration frequency, clamp versatility, and modular gearbox design for precise soil response matching—critical for marine and urban piling operations.

In Spain’s national infrastructure projects (Puertos del Estado, 2021), hydraulic vibro hammers demonstrated 25% faster installation times compared to traditional impact systems, supporting BRUCE’s field claims.

2. Decades of Global Success, Now Focused on U.S. Project Needs

-

With decades in manufacturing excellence and ISO-9001 certification, BRUCE’s equipment has proven its durability in diverse environments—including U.S. marine bridges, urban infrastructure, and coastal foundations.

-

-

Denmark’s offshore wind energy studies (DTU, 2020) confirmed that vibration-based hammers with noise-suppression kits, such as BRUCE’s SGV series, comply with marine environmental standards while maintaining installation speed.

3. Why U.S. Buyers Choose BRUCE

| Feature |

U.S. Project Benefit |

| Heavy-duty elastomers & clamping systems |

Supports diverse pile profiles—sheet, casing, tubed |

| Modular hydraulic design |

Eases setup on cranes, excavators, urban rigs |

| Precise remote controls |

Enhances performance tracking and operator safety |

4. FAQ — What U.S. Buyers Need to Know

Q1. Are BRUCE’s vibratory hammers tested for U.S. marine use?

Yes—they meet environmental noise standards with vibration-dampening design and remote control precision.

Q2. Can I trust BRUCE for long-term field reliability?

Yes—ISO-certified manufacturing and modular components ensure durable, low-maintenance operations.

Q3. What range of applications do these hammers support?

Designed for flexibility: selectable frequencies, customizable clamps, and adaptable mounting options for diverse U.S. soil and worksite conditions.

Q4: How does BRUCE comply with global piling regulations?

BRUCE vibratory hammers are engineered to align with U.S. EPA noise rules, U.K. ICE piling standards, Spain’s port authority guidelines, and Denmark’s offshore environmental codes.

Elevate your site performance with BRUCE, the leading vibro hammer company known for precision and durability.

👉Follow us on LinkedIn

for latest U.S. project highlights.

Across the U.S., Spain, and Denmark, BRUCE continues to define what it means to be a “top-notch vibro hammer company”—offering efficiency, safety, and proven compliance backed by peer-reviewed research and international case studies.

👉 Explore more at www.powerquip.co.kr

👉 Follow BRUCE Piling Equipment on LinkedIn

👉 See project visuals on Pinterest

📩 Contact [email protected] for tailored U.S. vibro hammer solutions.