Vibro Vibratory Hammer in Europe – Case Studies from England, Spain, and Denmark

JH KIM

view : 64

Introduction

Across Europe, piling equipment plays a critical role in marine, offshore, and urban infrastructure projects. Among the most important tools are vibro hammer and vibratory hammer, valued for their ability to deliver precision, efficiency, and environmental compliance.

This article highlights case studies from England, Spain, and Denmark, three regions where piling technology directly impacts national infrastructure goals. By analyzing these applications, contractors and engineers can better understand how to choose and apply the right hammer for diverse conditions.

Understanding Vibro and Vibratory Hammers

-

– Vibro Hammer: A commonly used commercial term for hydraulic-driven hammers designed to install sheet piles, H-beams, or casing piles quickly.

-

– Vibratory Hammer: The technical designation, describing machines equipped with eccentric rotating weights, hydraulic clamps, and frequency adjustment for efficient driving and extraction.

Both tools share:

-

· Reduced ground resistance → faster penetration.

-

· Noise-reduction options → compliance with urban and marine regulations.

-

· Durability → designed for long service life in harsh conditions.

Case Study: England – Bridges and Coastal Protection

England is investing heavily in urban transport upgrades and flood defense systems.

-

· Thames Infrastructure Projects: Vibratory hammers provide precision for bridge piling along the Thames. Operators can adjust ram stroke height to ensure stability in variable soils.

-

· East Coast Flood Defenses: Vibro hammers with silence cap housings minimize disturbance near residential areas while driving sheet piles for seawall reinforcement.

-

· Urban Rail Extensions: Compact hammers enable efficient work in confined city construction zones with strict noise restrictions.

· Key Insight

In England, regulatory compliance is central. Hydraulic vibratory hammers replace diesel options to meet environmental and acoustic standards without sacrificing productivity.

Case Study: Spain – Ports and Renewable Energy

· Spain’s strategic coastal position and renewable energy ambitions drive demand for advanced piling equipment.

-

· Barcelona Harbor Expansion: Vibro hammers have been deployed to install casing piles in seawalls, ensuring harbor durability.

-

· Canary Islands Offshore Wind: Vibratory hammers allow frequency adjustments to adapt pile penetration to seabed conditions.

-

· Andalusian Solar Farm Infrastructure: Steel sheet piles are reinforced with hydraulic hammers to stabilize energy plant foundations.

Key Insight

Spain’s combination of marine construction and renewable energy projects makes it a growth market for contractors who rely on reliable piling equipment.

Case Study: Denmark – Offshore Wind Leadership

Denmark is a global leader in offshore wind energy, and vibratory hammers are critical in this sector.

-

· North Sea Offshore Farms: Large-diameter monopiles are installed with hydraulic vibratory hammers capable of over 80 ton·m impact energy.

-

· Copenhagen Harbor Works: Projects emphasize eco-friendly hydraulic oils to protect marine ecosystems.

-

· Urban Redevelopment: Vibro hammers are applied in bridge and tunnel foundations with remote-controlled safety systems.

· Key Insight

Denmark’s environmental regulations demand piling equipment that combines power with compliance, positioning hydraulic vibratory hammers as the standard solution.

Comparative Benefits Across Europe

| Feature | Vibro/Vibratory Hammer | Diesel Hammer |

|---|---|---|

| Noise & Emissions | Low-noise, bio hydraulic oils | High emissions, noisy |

| Energy Control | Adjustable stroke & frequency | Fixed, less efficient |

| Suitability | Offshore, urban, marine projects | Limited in strict zones |

| Efficiency | Faster cycles, less downtime | Slower, higher maintenance |

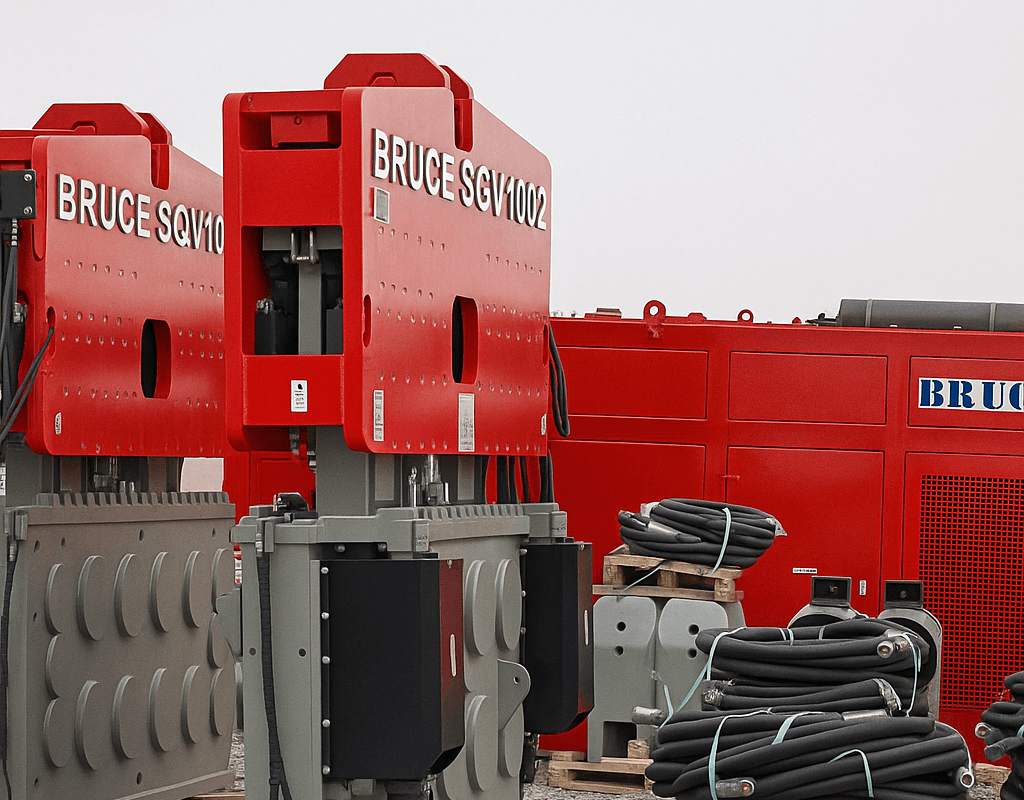

Why Contractors Choose BRUCE Technology

· Proven Track Record: More than 27 years of global piling equipment expertise.

· Adaptability: Equipment applied in offshore wind, harbors, and urban zones across Europe.

· Innovations: Remote monitoring, real-time diagnostics, and silence caps.

· Sustainability: Biodegradable oils and eco-friendly design meet European standards.

👉 Learn more about Hydraulic Pile Hammer Features

FAQs

1. What is the difference between a vibro hammer and a vibratory hammer?

Vibro hammer is the commercial term, while vibratory hammer refers to the technical hydraulic system.

2. Why are vibratory hammers popular in Denmark?

Because of their low noise and compliance with offshore wind environmental regulations.

3. Can vibro hammers be used in Spanish ports?

Yes, they are widely used for seawalls, harbors, and coastal reinforcement.

4. Are hydraulic vibratory hammers suitable for England’s urban projects?

Yes, they operate within strict noise/vibration limits and ensure precision in pile driving.

5. How do BRUCE hammers support renewable energy projects?

They provide energy monitoring and efficient installation of monopiles for wind and solar infrastructure.

Conclusion

· Vibro and vibratory hammers are at the heart of Europe’s foundation works, from England’s flood defenses, to Spain’s port expansions, to Denmark’s offshore wind farms. Their combination of efficiency, compliance, and reliability ensures they remain the equipment of choice for contractors facing modern challenges.

For detailed specifications and tailored consultation, please visit the official Contact Us page.

Explore more: