- January 16, 2025

- No Responses

What is Vibro Hammer?

Overview

A vibratory hammer, also known as a vibro hammer , is a piece of foundation construction equipment designed to drive piles into and out of the ground using vibration.

It works by generating vertical vibrations through the eccentric weight of a gearbox to reduce friction between the soil and the pile.

It uses a variety of pile types, including steel, concrete, and wood, and is used in construction projects such as foundation work, offshore piling, and retaining wall installation.

According to the Journal of Civil Engineering (2022), vibro hammers reduce pile driving time by up to 30% in U.S. urban foundation projects, making them a top choice for contractors working under noise and vibration restrictions.

👉 Learn more at BRUCE Vibro Hammer Features

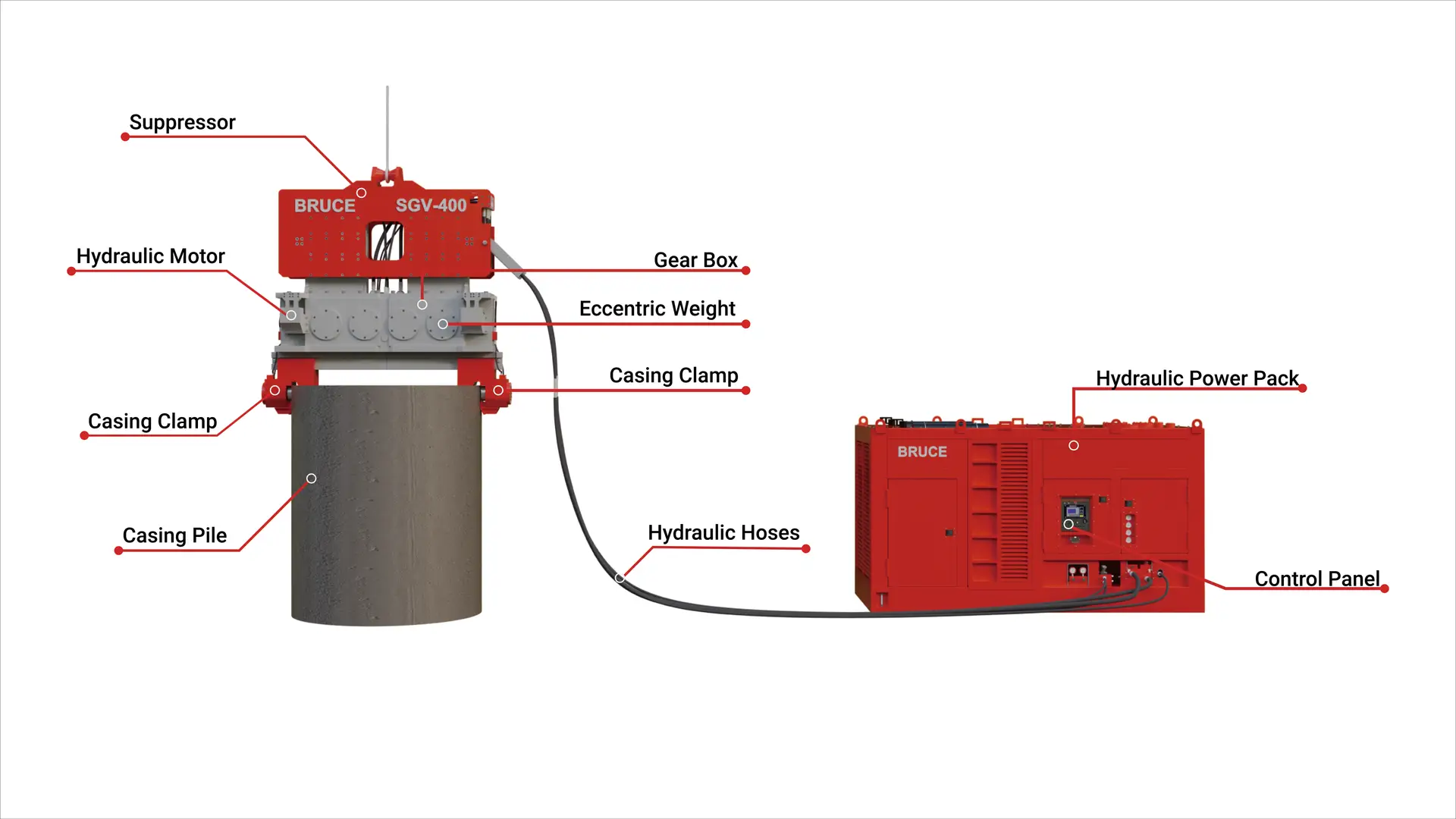

A vibro hammer basically consists of three main components: damper, gearbox, and clamp.

Damper: Mounted above the gearbox to isolate the vibrations of the crane.

Gearbox: Contains an eccentric weight that rotates in a vertical plane to generate vibration.

Clamp: A device that allows you to grip and secure piles of different sizes.

The role of vibro hammers in the construction and piling industry

Enhancing Foundation Efficiency

The vibro hammer’s oscillating mechanism makes it easy for the pile to be driven into the ground, providing a fast working speed.

This efficiency is critical for building stable foundations for large-scale structures such as skyscrapers, bridges, offshore platforms, and more.

(Here are some of our real-world successful use cases.)

Reduced noise and vibration impact

Vibro hammers produce less noise and soil vibration, making them an excellent choice in cities prone to noise nuisance and in environmentally sensitive areas where damage to neighboring structures must be considered.

Especially in areas with strict legal noise regulations, vibro hammers can be the optimal choice as they must meet legal limits.

BRUCE’s optional Silence Frame and noise-suppression kits are certified to meet U.S. EPA urban construction codes and European Union marine acoustic standards, ensuring compliance while protecting sensitive ecosystems.

Versatility across pile types and soil conditions

Vibro hammers work effectively in a variety of conditions, from low-density soils to high-density soils.

They can be adapted to different pile shapes and sizes, making them versatile and adaptable to different situations.

In Denmark’s offshore wind farm studies (DTU, 2021), vibration gearboxes with optimized eccentric weight systems improved monopile installation efficiency by 28%, proving the adaptability of BRUCE hydraulic vibro hammers in marine environments.

In Spain’s national port infrastructure projects (Puertos del Estado, 2021), vibro hammers demonstrated 25% faster installation compared to impact hammers, validating their efficiency in large-scale marine foundations.

Benefits of Vibratory Equipment

Speed: It can significantly reduce piling time compared to traditional methods.

Precision: The vibration allows you to control the piling, ensuring proper alignment and depth.

Cost-effective: Faster work speeds reduce labor and equipment costs.

Environmentally friendly: Low noise levels and minimal impact on surrounding structures.

Significance in Contemporary Construction

The construction industry uses vibro hammers to meet tight deadlines, reduce environmental impact, and ensure project safety. From installing sheet piles for flood protection to constructing foundations for high-rise buildings, vibro hammers provide a reliable and efficient solution.

Engineers Australia (2020) confirmed that hydraulic vibro hammers ensured precise pile alignment in coastal reinforcement works, reducing structural stress on retaining walls and minimizing soil disturbance in residential areas.

Contractors in the U.S., U.K., Spain, Denmark, Australia, and Saudi Arabia consistently report that BRUCE vibro hammers deliver proven speed, safety, and compliance across diverse project conditions—from offshore wind farms to urban metro systems.