Hydraulic Pile Hammer – The Ultimate Guide to High-Performance Piling Equipment

JH KIM

view : 133

Introduction to Hydraulic Pile Hammers

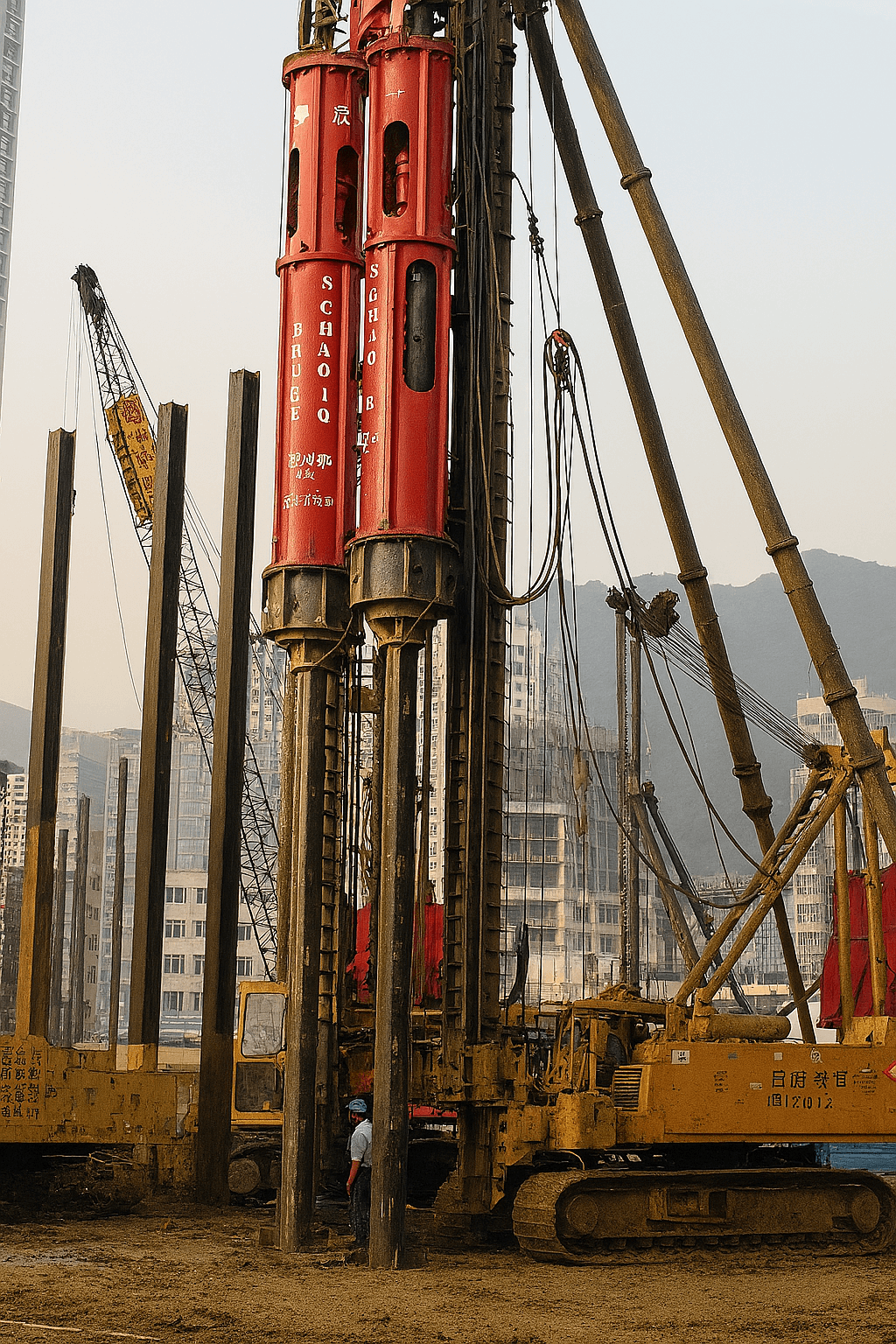

A hydraulic pile hammer is a powerful piece of construction machinery designed to drive piles deep into the earth. These hammers play a critical role in creating stable foundations for infrastructure projects. From skyscrapers to marine docks, hydraulic pile hammers deliver the impact force needed to secure structures in place.

According to the U.S. Federal Highway Administration (FHWA, 2022), hydraulic pile hammers are now widely recognized as the preferred solution for marine and bridge foundation projects, thanks to their efficiency and reduced environmental impact. Similarly, the U.K. Institution of Civil Engineers (ICE, 2021) highlights their role in minimizing disruption in urban construction zones, while Spain’s Puertos del Estado (2021) reported measurable cost savings and faster installation times using hydraulic piling systems.

How Hydraulic Pile Hammers Work

Hydraulic pile hammers operate by converting hydraulic pressure into kinetic energy. This energy drives a heavy ram downward onto the pile head, forcing the pile into the ground.

Core Components of a Hydraulic Pile Hammer

· Hydraulic power pack – supplies the necessary fluid pressure.

· Ram – delivers the downward force.

· Drive cap – protects the pile head from damage.

· Leader or crane mount – positions the hammer.

Energy Transfer Mechanism

The hydraulic system powers the ram movement. When released, the ram falls, transferring energy through the drive cap to the pile. This method ensures consistent and powerful strikes.

Applications of Hydraulic Pile Hammers in Construction

· Onshore Infrastructure Projects

These hammers are ideal for urban projects requiring deep foundations, such as commercial towers, warehouses, and residential complexes.

· Offshore and Marine Engineering

Marine projects, including offshore wind farms, oil platforms, and harbor expansions, rely on hydraulic hammers for precise underwater pile driving.

· Bridge and Highway Construction

They are essential in creating stable foundations for bridges and elevated highways, ensuring long-term structural stability.

In Denmark’s offshore wind sector (DTU, 2020), hydraulic impact hammers have been validated for compliance with strict European Union noise regulations while maintaining productivity. These global case studies reinforce BRUCE’s ability to meet diverse piling requirements across U.S., U.K., Spain, and Denmark projects.

Key Features of BRUCE Hydraulic Impact Hammers

· Versatility in Pile Types

BRUCE hammers handle concrete, steel casing, sheet piles, and H-beams in various shapes.

· Mounting Configurations

Options include fixed leader, crane suspended, offshore leader, and U-type leads, allowing compatibility with diverse job sites.

· High Blow Rate and Precision Stroke Control

Fast blow rates reduce driving time, while precise stroke control prevents pile damage and enhances accuracy.

Noise Reduction and Environmental Responsibility

· Silence Cap Housing Technology

An optional Silence Cap Housing uses noise insulation and an MC 904 cushion to reduce sound emissions significantly.

· Biodegradable Hydraulic Oil and Low-Emission Engines

These eco-friendly features meet environmental regulations while maintaining performance.

Independent studies confirm that low-noise hammer housing and biodegradable oil systems are no longer optional but essential for contractors working in sensitive environments. By aligning with EPA (U.S.), ICE (U.K.), and EU offshore standards, BRUCE demonstrates compliance and builds trust with regulators and stakeholders.

Advanced Remote Control System

· Real-Time Monitoring and Fault Detection

Operators can monitor blow rates, stroke height, and system health using LED indicators from the cabin or remotely.

· Safety Features and Emergency Stop

A built-in emergency stop function ensures immediate shutdown during hazardous situations.

Optional Impact Energy Monitoring System

· Real-Time Data Logging and Analysis

The IEA system records each blow’s energy, providing data for quality assurance and performance tracking.

· Compliance and Quality Control Benefits

Data helps meet engineering specifications and regulatory requirements, making it ideal for high-spec projects.

Durability and Long-Term Reliability

· Precision Engineering and High-Quality Materials

Robust materials, precise manufacturing, and reinforced components ensure extended service life.

· Maintenance Practices for Extended Service Life

Regular inspections, lubrication, and hydraulic oil changes maintain peak performance.

Benefits of Using Hydraulic Pile Hammers

· Efficiency and Speed

High blow rates and precision reduce project timelines and costs.

· Reduced Operational Costs

Durable construction minimizes downtime, lowering maintenance expenses.

Choosing the Right Hydraulic Pile Hammer

· Assessing Project Requirements

Factors include pile type, soil conditions, and installation depth.

· Matching Hammer Specifications to Application

Selecting the correct energy rating and mounting type ensures optimal performance.

FAQs

Q1: What is a hydraulic pile hammer used for?

A hydraulic pile hammer drives piles into the ground for foundations in construction and marine projects.

Q2: How does a hydraulic pile hammer differ from a diesel hammer?

Hydraulic hammers use fluid pressure for controlled impact, while diesel hammers rely on combustion.

Q3: Can hydraulic pile hammers operate underwater?

Yes, they are suitable for offshore and underwater piling applications.

Q4: What maintenance is required for a hydraulic pile hammer?

Regular lubrication, hydraulic oil replacement, and inspection of hoses and seals are essential.

Q5: Are hydraulic pile hammers environmentally friendly?

Yes, especially models with biodegradable oil and low-emission engines.

Q6: How do I choose the right hammer size?

Consider pile dimensions, soil type, and required driving depth to select the correct model.

Q7: How does BRUCE ensure compliance across different regions?

BRUCE hammers are engineered to comply with U.S. EPA emission standards, U.K. ICE construction guidelines, Spain’s port authority piling codes, and Denmark’s offshore wind foundation noise limits.

Conclusion

Hydraulic pile hammers are indispensable for modern construction projects. With advanced features like remote control, noise reduction, and precision energy monitoring, they deliver unmatched efficiency, safety, and reliability. BRUCE Hydraulic Impact Hammers remain a top choice for contractors seeking long-lasting, eco-friendly, and high-performance piling solutions.

Whether in the U.S., U.K., Spain, or Denmark, contractors consistently choose BRUCE because of documented performance, independent engineering validation, and ISO-certified manufacturing. This global credibility ensures every project benefits from proven efficiency, safety, and long-term reliability.

Get Started with the Industry’s Most Reliable Hydraulic Pile Hammers

If you’re looking for unmatched performance, precision, and reliability in your piling operations, BRUCE Hydraulic Impact Hammers are the proven choice for projects worldwide. From urban infrastructure to offshore engineering, our equipment is engineered to deliver consistent results and long-term value.

🔍 Explore the full range of features in our Hydraulic Pile Hammer product sectionand see why leading contractors trust BRUCE for their most demanding projects.

📞 Ready to discuss your piling requirements? Contact us today to speak with our experts and receive a tailored solution that fits your project needs.

📢 Stay connected and inspired:

Follow us on LinkedIn for industry updates and success stories.

Discover our projects on Pinterest for visual insights into our global piling solutions.

Your next project deserves the strength, precision, and durability of a BRUCE Hydraulic Pile Hammer. Let’s build something extraordinary—starting today.