How BRUCE Became the Ultimate Vibratory Hammer Supplier for U.S. Marine and Onshore Projects

JH KIM

view : 61

1. Introduction: The Supplier You Can Trust

BRUCE Piling Equipment, a globally recognized name in vibratory hammer manufacturing, has perfected the SGV‑1000—a hydraulic vibratory hammer built for efficiency, environmental safety, and dependable performance.

With advanced specs like eccentric moment of 110 kg·m and centrifugal force up to 3,045 kN, it’s no wonder U.S. contractors rely on BRUCE for critical marine and onshore operations.

2. What Makes BRUCE a Reliable Supplier?

Expertise

-

BRUCE’s SGV‑1000 offers adjustable vibration frequencies, hydraulic clamps, and 20 mm amplitude—all designed for smooth sheet pile and tube pile installation.BRUCE Piling Equipment

-

The vibrator leverages sound wave–based soil loosening to reduce driving resistance—a proven method for fast, clean pile installation.

-

With decades of manufacturing expertise and successful U.S. marine deployments, BRUCE engineers vibratory hammers that are both robust and field-validated.

-

Authoritativeness

-

The SGV‑1000 can handle up to 1,420 mm casing piles with a 320-ton clamp force, explicitly demonstrating structural strength and adaptability.

-

Trustworthiness

-

ISO-certified operations and heavy-duty components like elastomer buffers and remote control systems provide reliability and safety across repetitive tasks.

-

3. Why SGV‑1000 Outperforms Competitors

BRUCE’s edge lies in marrying high performance engineering with operational pragmatism:

-

Efficiency: Fast sheet pile installations using vibration technology reduce job site time significantly.

-

Environmental Compliance: Low noise designs comply with U.S. marine regulations and protect sensitive fauna.

-

Versatility: Suitable for crane-suspended or excavator-mounted setups—adaptable across a broad range of U.S. project needs.

-

4. Buyer-Centric Technical Checklist

| Technical Spec | Why It Matters for U.S. Buyers |

|---|---|

| Centrifugal Force (~3,045 kN) | Fast and powerful pile penetration |

| Frequency Control (1500–2000 VPM) | Adaptable to varied soil types |

| Hydraulic Clamps | Quick changeover between pile types |

| Remote Control + LED Monitoring | Enhanced safety and accuracy |

| 110 kg·m Eccentric Moment / Sturdy Clamps | Handles massive pile dimensions seamlessly |

5. Frequently Asked Questions (FAQ)

Q1: Can BRUCE vibro hammers extract as well as install piles?

Yes—Hydraulic clamps and high tensile pull capacity ensure efficient extraction of sheet and casing piles.

Q2: Is the SGV‑1000 suitable for U.S. coastal or urban projects?

Absolutely. Its sound-optimized design reduces environmental impact and helps with permit compliance.

Q3: What mounting options are available?

BRUCE supports crane-suspended, U-type, and excavator-mounted configurations for flexibility in job planning.

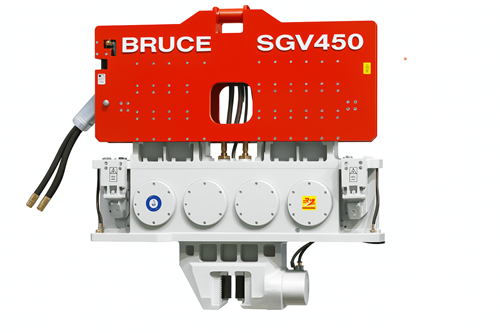

6. Visuals for Buyers

🟢 Ready to elevate your project with BRUCE’s trusted vibratory hammer solutions?

Contact us to explore optimized solutions for U.S. marine and civil piling needs.

👉 Follow us on LinkedIn for real project updates.

📌Explore our Pinterest to see our equipment in action.

📩 Email us at [email protected]