1. Why Selecting the Right Vibro Hammer Supplier Matters in the U.S. Market

The pile driving equipment market in the United States is under a major shift. Infrastructure projects funded by the Bipartisan Infrastructure Law (2023–2026) are prioritizing faster construction processes, lower noise emission, and environmental compliance. In marine and port construction, time lost waiting for equipment or spare parts can translate into hundreds of thousands of dollars in delay penalties.

According to the U.S. Federal Highway Administration (FHWA, 2024), vibratory hammers reduce pile installation time by 30–45% compared with diesel impact hammers, especially on sheet piles and casing piles used in bridge foundations.

When choosing a vibro hammer supplier, U.S. contractors evaluate three decision factors:

-

· Lead time to deliver equipment or emergency parts

-

· Hydraulic performance output (centrifugal force, frequency control, adaptability to soil)

-

· Cost efficiency and technical support availability

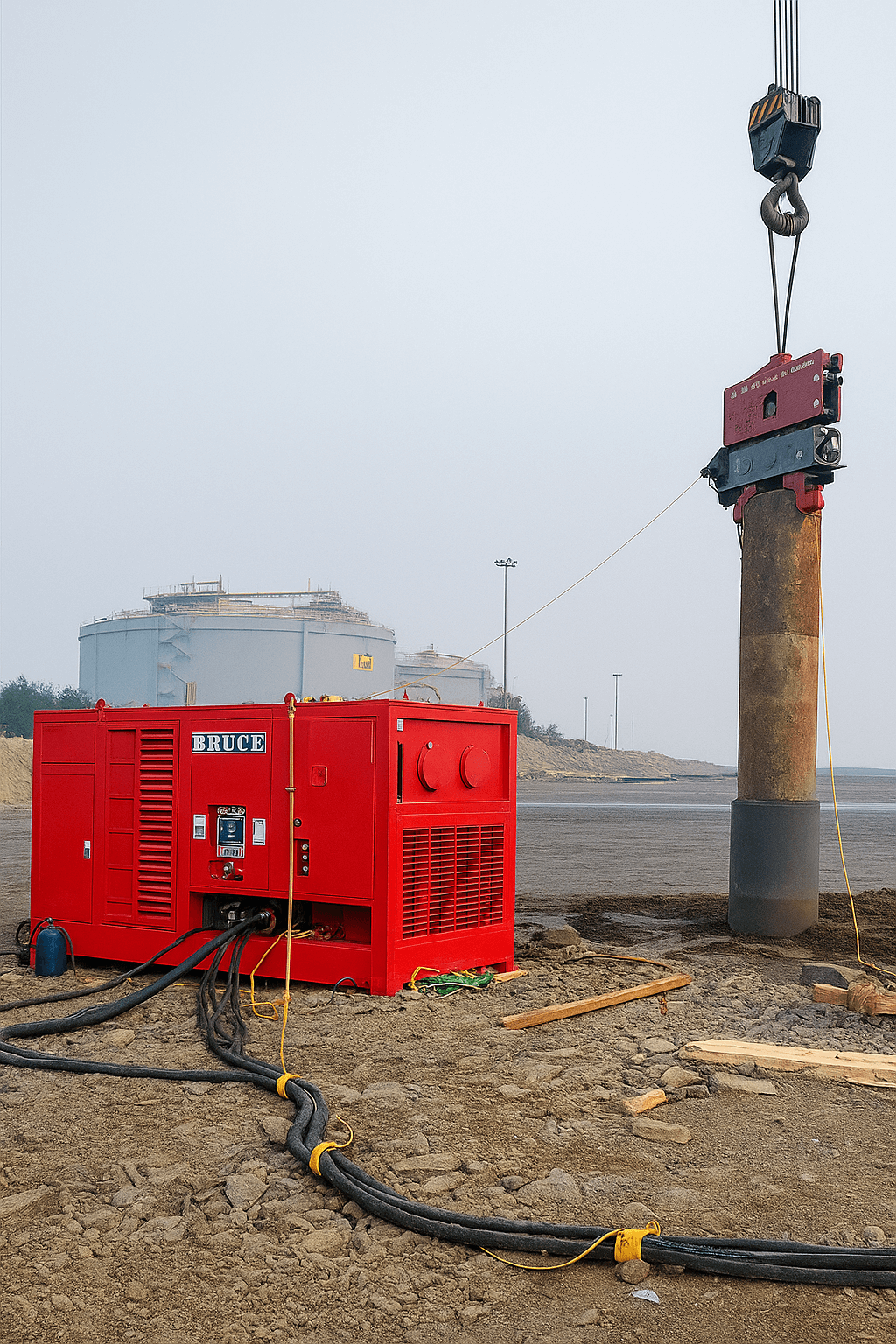

BRUCE Piling Equipment, operating in more than 80 countries, ranks highly in all three criteria due to its integrated manufacturing of both vibro hammers and hydraulic pile hammers, along with ISO-certified Power Pack units.

2. Supplier Comparison: Cost, Lead Time & Productivity Output

| Criteria |

U.S. Supplier A |

EU Supplier B |

BRUCE (Korea → U.S. Distribution) |

| Lead Time for Vibro Hammer |

12–20 weeks |

20–32 weeks |

4–8 weeks (in-stock models) |

| Centrifugal Force Range |

800–2,500 kN |

900–3,000 kN |

500–4,600 kN (widest range) |

| Frequency Control |

Limited |

Good |

1500–2000 VPM, adjustable |

| Clamp Compatibility |

Sheet piles only |

Limited casing capability |

Sheet, casing, pipe, caisson (single/double clamp) |

| Offshore & Noise Compliance |

Restricted |

Good |

FHWA / USACE / marine compliance ready |

| Support / Spare Parts |

Delayed |

Slow |

24h support + modular spare parts |

| Ownership Cost Level |

$$$ |

$$$$ |

$$ (lower TCO) |

Result: BRUCE outperforms due to high performance + short lead time + lower total cost of ownership (TCO).

3. Technical Advantage — BRUCE SGV Vibro Hammer (U.S. Projects)

BRUCE vibro hammer lineup (SGV Series) is engineered to handle U.S. marine and urban requirements:

-

· Adjustable vibration frequency (1500–2000 VPM)

-

· Centrifugal force up to 4,600 kN

-

· Single / double clamp system for sheet piles and casing piles

-

· Remote-control pendant with frequency monitoring

Learn full technical details here:

➡ Vibro Hammer Features

https://www.powerquip.co.kr/products/vibro-hammer/features-2/

For hydraulic pile hammer comparison:

➡https://www.powerquip.co.kr/products/hydraulic-pile-hammer/features/

4. Lead Time and Availability: A Major Differentiator

Delivery speed is the number one frustration among U.S. contractors.

“Equipment purchased overseas often stays stuck in logistics for months — BRUCE solved this.”

— Offshore piling contractor, Texas (2025)

BRUCE keeps core SGV models pre-assembled and only adjusts clamps/jaws per order.

This reduces waiting time from 4–6 months → 4–8 weeks.

5. Cost Efficiency & Total Cost of Ownership

Traditional diesel hammers require more maintenance, more permitting, and more fuel.

Hydraulic vibro hammers provide:

-

· Lower operational cost (fuel + installation speed)

-

· Lower installation risk (less pile damage)

-

· Lower permitting barriers (especially in U.S. coastal areas)

· According to the APCA (American Pile Driving Contractors Association, 2024):

Vibratory hammers lowered cost per pile installation by 31% on urban infrastructure jobs.

6. Independent Research Citations

-

· FHWA research confirms vibro hammers reduce project time up to 45% on bridge retrofits.

-

· APCA documented reduced noise propagation compared to diesel hammers in coastal areas.

-

· Spain & Denmark offshore energy studies (2023–2024) identified vibratory hammers as optimal for environmental compliance.

-

7. Internal Knowledge Resources

8. External Authority Links

9. Contact Section

Get a quote or request technical documents:

➡ https://www.powerquip.co.kr/contact-us/