Introduction

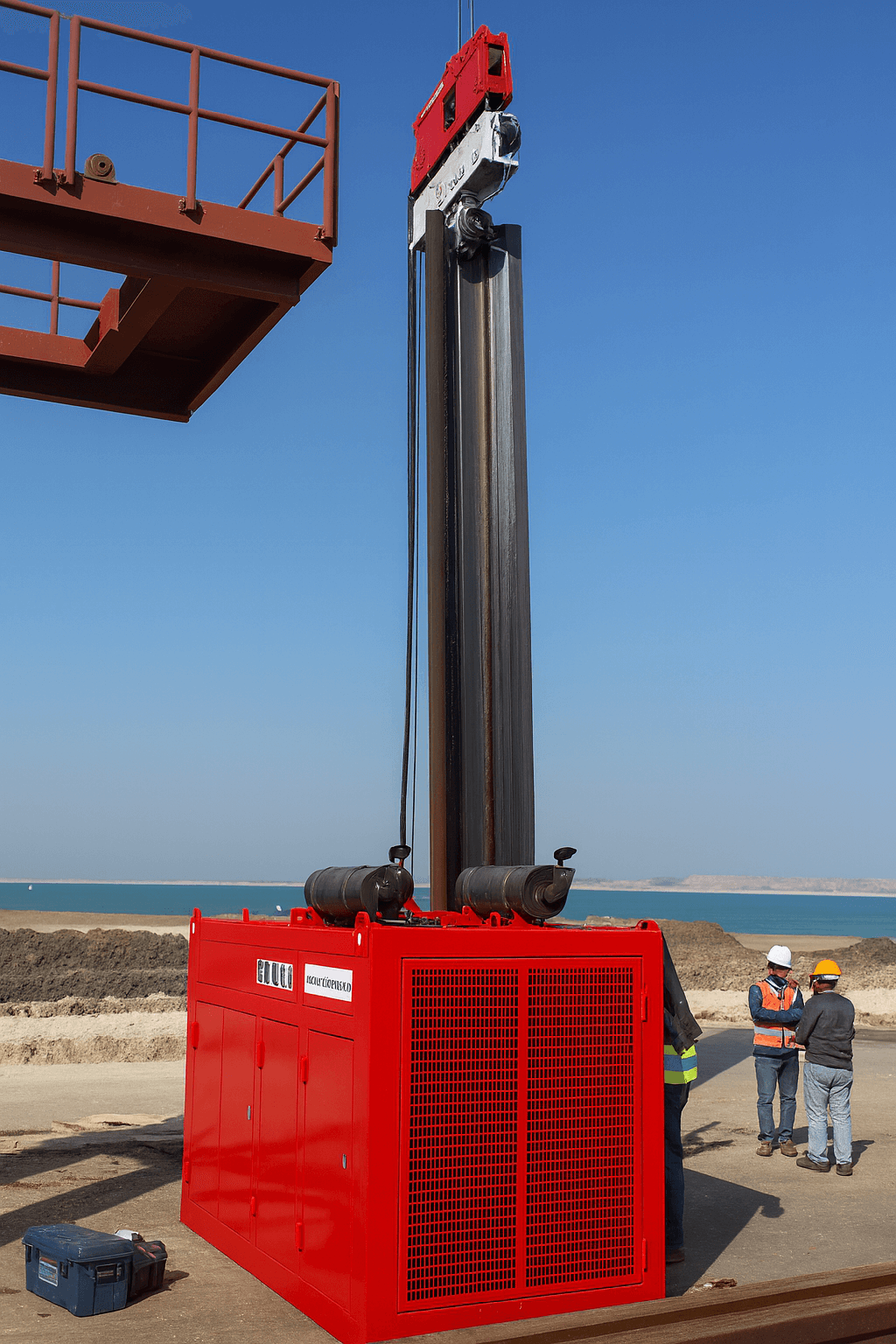

Modern infrastructure projects require efficient, safe, and sustainable pile driving solutions. Vibro and vibratory hammers have emerged as core technologies for offshore wind farms, bridges, ports, and marine foundations.

While both terms are often used interchangeably, vibro hammer is typically associated with equipment supply, whereas vibratory hammer refers to the broader technical and operational perspective. Understanding their technology and applications provides valuable insight into why they are indispensable in the U.S., U.K., Australia, and Saudi Arabia.

Technology Overview

· Generates vertical vibrations through eccentric rotating weights.

· Reduces soil resistance → faster penetration of piles.

· Commonly used for sheet piles, H-beams, and casing piles.

Vibratory Hammer

· Hydraulic vibratory systems with frequency control and adjustable amplitude.

· Equipped with hydraulic clamps for different pile profiles.

· Used for both pile driving and extraction in diverse conditions.

👉 Learn more about Vibro Hammer Features

Case Study: United States

·Offshore Wind Farms (East Coast): Vibratory hammers deliver up to 85.5 ton·m impact energy, essential for monopile foundations.

·Urban Infrastructure (New York, Boston): Low-noise operation supports projects near residential zones.

·Bridge Foundations: Hydraulic control ensures stability and prevents pile damage.

Case Study: United Kingdom

·North Sea Offshore Wind: Silence cap housings reduce noise to comply with strict U.K. marine regulations.

·Thames River Bridge Works: Ram stroke visibility enhances precision in piling operations.

· U.K. regulations accelerate the shift from diesel to hydraulic vibratory hammers.

Case Study: Australia

·Coastal Defense Projects: Vibro hammers applied in seawalls and harbor reinforcement.

·Mining Infrastructure: Heavy-duty piling in remote areas requires durable hydraulic systems.

·Transport Expansions: Rail and highway retaining walls built with vibratory hammers.

Case Study: Saudi Arabia

· NEOM and Red Sea Projects: Large-scale offshore and desert foundations demand high-capacity hammers.

· Harsh Climate Adaptation: Advanced cooling systems prevent overheating in desert conditions.

· Port Expansions: Double clamp vibratory hammers drive spiral pipe piles efficiently.

Comparative Analysis

| Criteria | Vibro/Vibratory Hammer | Diesel Impact Hammer |

|---|

| Efficiency | Faster driving/extraction | Slower cycles |

| Noise | Lower, soundproof options | High, regulated |

| Control | Adjustable frequency & stroke | Limited |

| Environmental | Bio-oil, low emissions | High emissions |

| Suitability | Offshore, urban, marine works | Heavy-duty only |

Global Market Trends

·U.S. & U.K.: Offshore wind and infrastructure expansion.

·Australia: Coastal resilience and mining demand.

·Saudi Arabia: Mega-project investment boosting piling activity.

For further details, explore Hydraulic Pile Hammer Features

Why BRUCE Equipment is Trusted Worldwide

·27+ years of expertise in pile driving technology.

·Proven reliability in U.S., U.K., Australia, and Saudi projects.

·Innovations: remote control, energy monitoring, silence housings.

·Sustainability: biodegradable hydraulic oils and low-emission systems.

Additional references:

FAQs

1. What is the difference between a vibro hammer and a vibratory hammer?

A vibro hammer is often used as a commercial term, while vibratory hammer refers to the broader technical system.

2. Are vibratory hammers suitable for offshore projects?

Yes, they are applied in offshore wind farms in the U.S., U.K., and Middle East.

3. Why are vibratory hammers replacing diesel impact hammers?

Because of stricter noise/emission regulations and higher efficiency.

4. How do they perform in harsh climates like Saudi Arabia?

Durable components and advanced cooling systems ensure reliable operation.

5. What industries in Australia benefit most?

Marine defense, harbor works, and mining infrastructure.

Conclusion

Vibro and vibratory hammers are redefining pile driving across the U.S., U.K., Australia, and Saudi Arabia. Their adaptability, environmental compliance, and proven reliability make them essential for both offshore and onshore projects.

For engineers and contractors exploring project-specific solutions and technical specifications, professional consultation is available through the official Contact Us channel.