A New Type of Piling at Florida, USA-BRUCE SGH-3013

JH KIM

view : 697

A New Type of Piling for Florida

SGH-3013

Pile Hammer

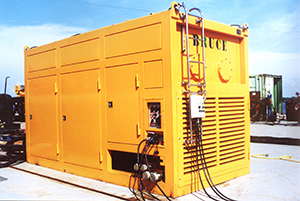

Hydraulic Pile HammerPower Pack

Power pack

Hydraulic Power PackHathaway Bridge Project

pile hammer

Hydraulic Pile Hammerpile hammer

Hydraulic Pile HammerGranite Construction Utilizes 60-In. Cylinder Piling on $81.5 Million Hathaway Bridge Project By Debra Wood

Introducing a type of bridge substructure that's new to Florida, California-based Granite Construction Co. is building sleek twin bridges to replace the outdated Hathaway Bridge across St. Andrews Bay, from the mainland to Panama City Beach.

Approximately 300 hollow 60-in.-diameter prestressed concrete cylinder pilings will support the twin bridges.

Cylinder piles are able to hold greater loads than traditional piles, enabling greater distances between piers.

“It reduced the number of piles needed,” said Doug Geiger, senior project engineer with the bridge’s construction engineering and inspection firm, Reynolds Smith and Hills (RS&H) Construction Services in Panama City.

“[The use of cylinder piles] lowers the overall price of construction and expedites the time. It cuts down on the time to drive the piles and do the foundation work.”

The 130-ft.-long piles are cast as one piece, with 7.5-in.-thick reinforcing walls and no joints.

Geiger has worked on more than 50 bridges throughout Florida and believes this is the first time the single-piece cylinder piles have been used in the state.

Standard Concrete Products, Tampa, is manufacturing the piles at a casting yard near the construction site.

They are barged to the site in lots of 10 to 20. In addition to the cylinder piles, there are a few 24-ft. square piles on land at the end of the bridges.

The two new bridges, with a total of eight 12-ft.-wide lanes, will replace existing, congested structures, built in 1929 and 1960, respectively.

The Florida Department of Transportation expects the new structures to improve pedestrian, bicycle and vehicle safety, enhance traffic flow, and expedite marine traffic.

Granite, with its Florida headquarters in Tampa, received the $81.5 million design-build contract in June of 2000, executed it in July 2000 and began work in August 2000.

The contract includes 3,814-lin.-ft. westbound and 3,383-lin.-ft. eastbound, 80-ft.-wide bridges, realignment of approach roadways, and demolition and removal of the existing Hathaway Bridge.

The different lengths of the east- and westbound bridges is due to the curve in the road and being able to use some of the existing causeway on the eastbound structure.

The bridge’s main span will be 330 ft. long, with 65 ft. of clearance for marine traffic on the intracoastal waterway.

HNTB Corp., Orlando, is the principle designer. Rizzani De Eccher USA, Aventura, will work with Granite on precasting and erection of the bridge’s concrete segmental box superstructure.

Granite began driving test piles in March 2001. Foundation crews were expected to start pouring footings and encapsulating pilings in October 2001.

Soil conditions vary across the bottom of the bay. Loose, fine sands comprise the upper layers, with medium to dense gray to green, clay-like fine sands in the lower layers.

Geiger described the environment as extremely aggressive, with chlorides exceeding 18,000 parts-per-million (ppm).

“We went to a microsilica concrete, which is more corrosion-resistant,

” Geiger said. “The chlorides from the salt water won’t intrude as much on a microsilica-type concrete. It’s a denser concrete.”

Pile groups vary from 12 piles to 22 per combined footing, with footings ranging in size from 1,200 to 1,400 cu. Yds. The ultimate bearing capacity will vary from 2,200 to 3,200 kips (kilopounds). Footings in the center channel have been designed to resist lateral ship impacts of up to 3,500 kips.

Those closer to shore have lower impact requirements.

For each pile, crews install a steel template, which serves as a guide for pile placement, then the pile is lowered into position and jetted.

A Manitowoc 4100W crane is mounted on a ringer pedestal on a 72-ft.-long, 250-ft.-wide, 5,400-ton-capacity barge called the Granite 1.

The crane is equipped with an additional 240-ft. boom from a Manitowoc 4600.

The crane lifts piles, the frame assembly and the hammer into place.

A Bruce model SGH 3013 hydraulic hammer, with a ram weight of 66,140 lbs., is used to drive the piles.

” The hydraulic pile hammer [is] 5 ft. across; a guy could stand inside the area where the piles are put in, called the helmet,” Geiger explained.

“When you think about the force [of] the 66,000-lb. ram times the 4-ft. drop, you’re talking about a potential energy of 225,000 lbs. of foot force.”

Piles are driven at a battered angle of 1 in. horizontal on 12 in. vertical to handle ship impacts. It takes between two and three hours to drive each pile.

“The equipment is bigger, on a larger scale [than on typical projects],” said Geiger, adding that the increased size adds to the pile-driving process.

“Setting up is time consuming with this big equipment.”

QORE Property Sciences of Montgomery, Ala., is conducting pile dynamic analysis (PDA) and monitoring installation.

While driving, gauges on the PDA predict the capacity of the pile based on a computer model with soil parameters.

PDA testing is done on a test pile in each foundation. With stronger soils, shorter piles can be used.

Applied Foundation Testing Inc., Green Cove Springs, is performing statnamic testing, which replaces standard load testing.

At presstime, the company had completed four 30-meganewton axial statnamic tests and two four-meganewton lateral statnamic tests at various locations across the bridge.

“It’s like a small rocket,” said Geiger of the device used to perform this testing.

“You set it on there with rocket fuel. It weighs a certain amount.

You ignite the fuel, and get thrust, which as you are lifting this mass, it is pushing down on the pile. You have internal gauges in the pile and you can tell the stresses, strains and capacities you have in the pile.”

The westbound, northernmost bridge will be completed first and opened to two-way traffic.

He existing bridge will then come down and construction will start on the eastbound structure.

Construction is scheduled for completion in the summer of 2003.

“We’ll all carry away from this, working with these 60-in. cylinder piles,” Geiger concluded.

“That’s an experience we are going to look back on and say, ‘This was pretty cool.'”

SGH-3013

Key Performance Specifications:

- • Max. Potential Energy: 39 ton.m /282,087 lbs

- • bpm: 26~60

- • Operating Pressure: 270 bar / 3,917 psi

- • Required Flow Rate: 600 lpm / 160 gpm