How a Vibro Hammer Improved Sheet Piling Efficiency in a U.S. Marine Project

JH KIM

view : 171

Introduction: Project Context

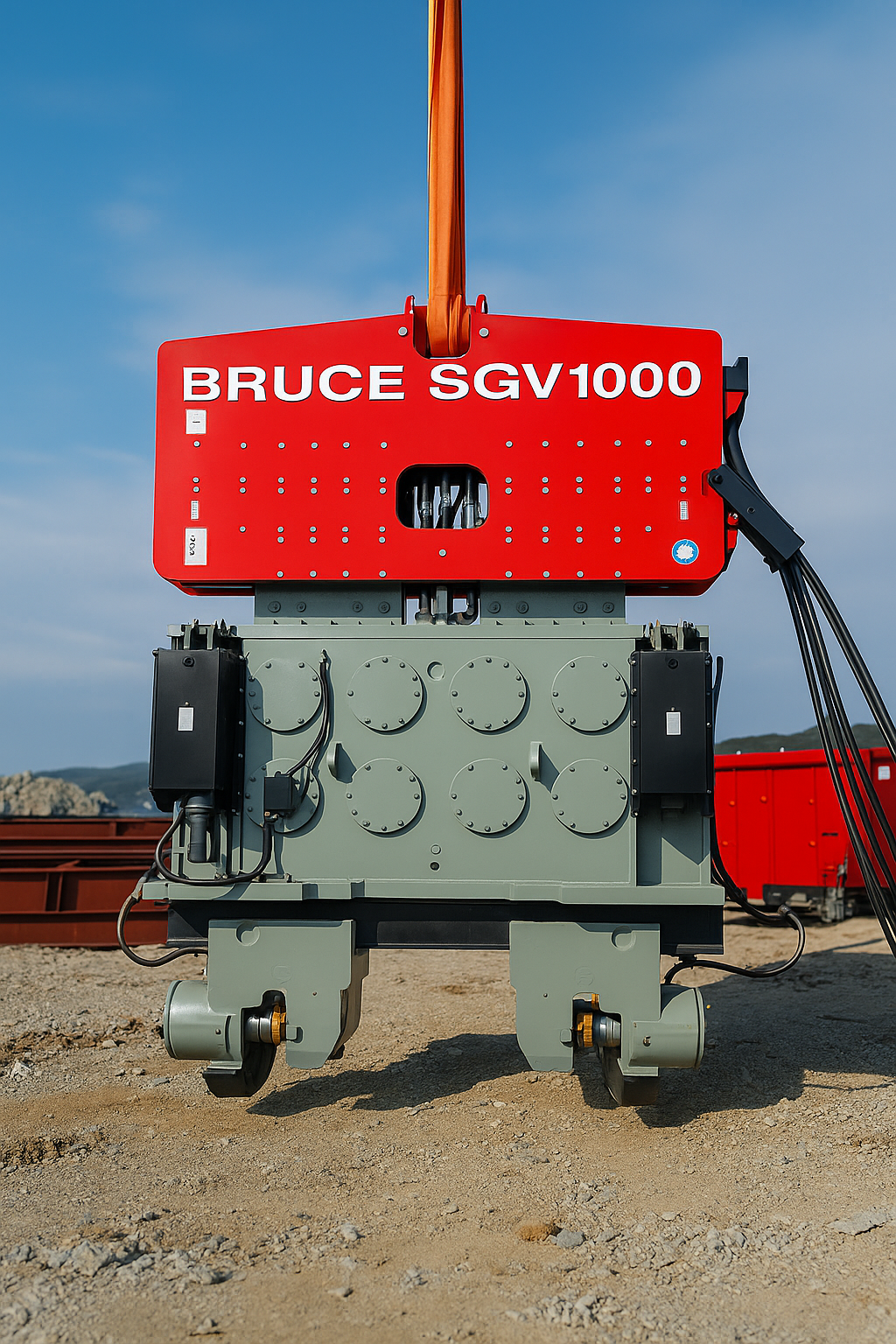

In early 2023, BRUCE’s SGV‑1000 vibro hammer played a critical role in constructing a coastal bridge foundation in the United States. The marine site required high-capacity equipment capable of efficient sheet pile installation and extraction in soft seabed conditions. The contractor selected BRUCE for its reputation in delivering durable and efficient vibratory hammer solutions.

Site Conditions & Equipment Setup

-

Location: U.S. coastal bridge site with tidal seabed

-

Pile Types: 1,020 mm diameter sheet and tube piles

-

Equipment: BRUCE SGV‑1000, installed on a 40‑ton excavator via 360° rotating mounting bracket

-

Energy Capacity: SGV‑1000 delivers centrifugal forces up to 3,045 kN, ideal for repetitive sheet pile cycles

Performance Impact: Time & Safety

-

Time Efficiency: Average pile penetration time reduced from 5–6 minutes (with impact methods) to under 2 minutes per sheet pile using the vibratory operation

-

Operational Precision: The hydraulic clamp system adjusted automatically between pile types, minimizing downtime and operator error

-

Noise and Vibration Control: High-grade elastomer isolators absorb over 90% of vibration, preserving both equipment integrity and marine species safety

Technical & Safety Features

-

Hydraulic Integration: Plug-and-play hose configuration enabled a fast setup without need for extensive hydraulics customization.

-

360° Rotatable Bracket: Allowed precise positioning from any angle, reducing repositioning time and improving site efficiency.

-

Durable Elastomer System: Shock absorption prevented machinery fatigue, improving lifespan and reducing maintenance intervals.

-

Operator Convenience: Simplified remote control allowed precise adjustment of vibration and clamp functions, improving safety and productivity on-site.

Why the SGV‑1000 Was the Ideal Choice

-

Specialized for Marine Conditions: Low-noise, continuous vibration minimized disruption in sensitive marine permits.

-

Versatile & Safe: Easy clamp transitions and excavator compatibility made it ideal for sites with restricted access.

-

Environmental Compliance: Reduced impulse noise meant compliance with local underwater sound regulations.

-

Trusted by Industry: BRUCE’s global export track record and ISO-9001 certification provide contractor confidence.

Conclusion

This case clearly illustrates how a high-performance BRUCE vibro hammer, specifically the SGV‑1000, can dramatically improve efficiency, safety, and compliance in marine construction. For U.S. contractors seeking reliable foundation solutions using vibratory hammer technology, BRUCE offers proven systems backed by experience.

👉 Contact BRUCE today to explore model options or request a quote tailored to your project needs.